One of the top questions brewers ask today is, “How is non-alcoholic beer made?” There are several ways to approach production, each yielding slightly different results.

Brewers must evaluate the different production methodologies to determine which one best suits their current processes and infrastructure. Next, they should consider the new beer style’s long-term plan and lifecycle.

There’s a lot to evaluate here. Before we get into how non-alcoholic beer is made, let’s examine why craft breweries should consider adding NA beer to their product lineup.

Why NA Beer? The Numbers Behind the Trend

With NA beer sales surging 30% from 2023 to 2024 — making it the third-fastest-growing beverage category — the opportunity is clear. The traditional U.S. beer market is leveling off, and forward-thinking producers are expanding into this explosive category.

Several key factors drive the growth of today’s NA beer category:

- A new generation of health-conscious consumers, with nearly 75% of Gen Z and millennials actively seeking non-alcoholic alternatives.

- High-quality products that deliver authentic beer experiences without the alcohol.

- Evolving consumer preferences that blend traditional and non-alcoholic options throughout occasions.

- Recent health guidance that may accelerate category growth.

While the shift toward NA may concern producers of full-alcohol beer, the picture is not so black and white. Many who drink NA beer also enjoy traditional beer. They may have a couple of full-strength beers with their friends and then top it off with an NA beer near closing time.

So, if you’re worried that expanding into NA beer will accelerate a shift away from your traditional beer styles, don’t be. Think of this as your next big opportunity. Beyond generating revenue, NA beer offers a path to broader engagement, driving awareness and creating multiple customer touchpoints.

What is NA Beer?

To understand how to make non-alcoholic beer, it’s essential to grasp some of the technical details of NA beer. Both regular beer and NA use many of the same ingredients, including:

- Water: The largest component

- Malted grains: Providing the fermentable sugars that contribute to color, body and sweetness

- Hops: Adding bitterness, aroma and flavor

- Yeast: The microorganism that ferments the sugars and produces alcohol and carbon dioxide

It’s also important to note that most NA beers available on the market are not 100% alcohol-free. The industry defines NA beer as any beer containing no more than 0.5% ABV, a level of alcohol that is too low to produce noticeable effects.

How is Non-Alcoholic Beer Made?

NA beer is produced using a variety of methods. For anyone new to the process, it can initially seem overwhelming. For the purposes of this blog, we’ll rely on an authoritative source: the Brewers Association (BA).

The BA sums up production in two ways: preventing alcohol from being formed or removing the alcohol after fermentation.

No Fermentation

This method is pretty straightforward. It involves producing wort but without the addition of yeast. (Yeast is what causes fermentation and produces alcohol.)

Limited or Arrested Fermentation

NA beer may also be produced by prematurely arresting the fermentation process or using yeast strains that are incapable of completing it. In this process, the wort is generally designed to be less fermentable than in a typical beer recipe.

Fermentation is stopped before high levels of alcohol can be produced. This is usually done by lowering the fermentation temperature to reduce yeast activity.

Special yeast strains may also be used in this process. Some of these strains are unable to ferment sugars such as maltose.

Dealcoholization

Dealcoholization is just like it sounds. This process involves removing the alcohol from the fermented product. There are several ways to accomplish this:

- Boiling: Since the boiling point of alcohol is lower than water, the beer can be heated to evaporate the ethanol while retaining the water. However, this can impact the product’s flavor by driving off other volatile aroma compounds.

- Vacuum distillation: This is similar to boiling beer, but it is conducted under a vacuum. Vacuum distillation reduces the temperature required to boil off ethanol from 78.4 C to 34 C, reducing the impact of temperature on the final product.

- Membrane filtration: A filter physically separates compounds such as alcohol by using a pressure differential between the two sides of the filter.

- Reverse osmosis: This technique is the most common type of membrane filtration used to produce non-alcoholic beers. As the beer passes across the membrane, small molecules like water and ethanol are removed. Water is then added back to the final product to account for the loss of water that occurred during the process.

NA Beer Quality Control Tips

Without alcohol’s natural preservation properties, NA beer requires extra attention to safety and stability. With an alcohol content below 0.5% ABV, the beer can become vulnerable to bacterial growth. Specific protocols must be implemented to keep consumers safe.

NA beer production can also result in high concentrations of fermentable sugars, elevated pH and low hop bittering compounds. A pH of 4.6 or lower must be maintained to help prevent microbial contamination.

To ensure the safety of your NA beer from brewery to consumer, consider these preservation methods:

- Pasteurization: Tunnel pasteurization is considered the most robust form since it occurs when the liquid is in the final package. Other kinds, such as flash pasteurization, are done in a clean room before the product is packaged.

- Sterile filtration: This process should only be carried out in a clean room for the filling equipment.

- Preservatives: Chemical and natural preservatives are used to create a microbially stable NA beer.

Food regulators may still conduct a safety check, so be prepared for a site visit or audit of your brewery.

Packaging & Delivery Matter

If you’re new to NA beer production, you may not be aware of the labeling requirements. NA beer requires specific messaging on the label to differentiate it from full-alcohol beer. If you use “non-alcoholic” on the label, you must also include “contains less than 0.5% ABV” in clear, legible print. Make sure to research all of the necessary components to keep your label compliant.

Next, carefully consider how your product is packaged. While NA beer is stable in bottles and cans, draft systems present unique challenges due to potential contamination during service. This isn’t surmountable, but it does require implementing proper safety protocols.

How to Scale Your NA Beer Operation

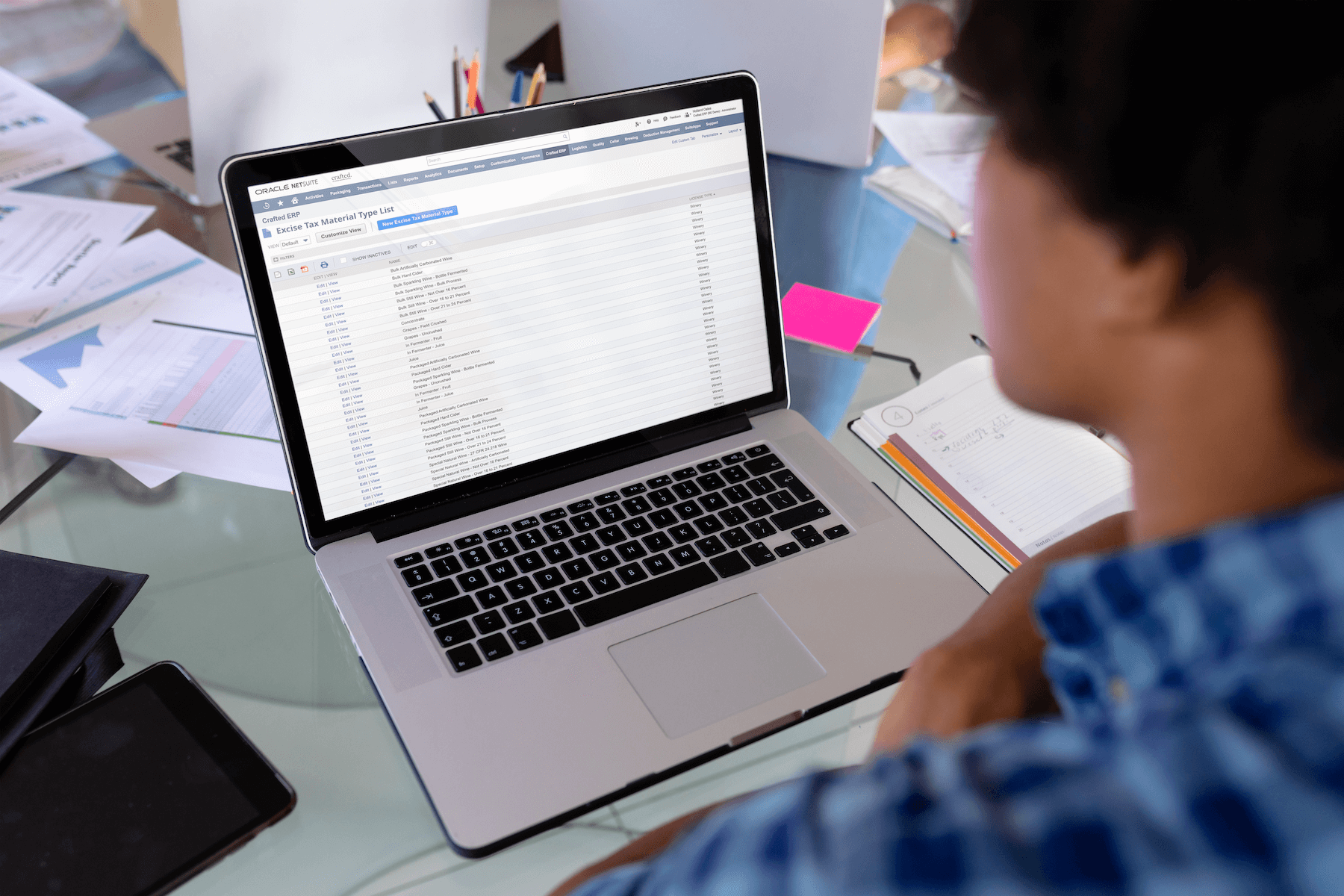

Like any strategic expansion, adding NA beer to your portfolio requires careful planning and the right tools. Here’s where Crafted ERP’s Non-Alc Edition comes in — our platform is specifically designed to help craft beer producers like you confidently enter new markets.

Just ask Athletic Brewing Co., one of today’s leading NA beer producers. As Co-Founder Bill Shufelt shares:

“We needed a platform that could seamlessly integrate with our website while allowing for recipe management, multi-location brewing, inventory fulfillment and more. NetSuite alone didn’t fit, but with Crafted’s brewery-specific functionality we were able to curate the solution to support Athletic Brewing’s aggressive growth strategy.“

Ready to Dive Into NA Beer?

With the right strategy and tools, you can expand your craft beer portfolio to include NA beer while maintaining the quality and consistency your customers expect.

Want to learn how Crafted ERP can help streamline your NA beer production? Contact us to discuss your diversification strategy.