Running out of your Christmas ale in early December? Painful. Watching pallets of pumpkin spice lager linger into February? Even worse. Both scenarios sting twice, once in the wallet and again in brand reputation.

Seasonal releases are a brewer’s paradox: they represent some of the highest-margin opportunities in craft beer, yet also some of the riskiest to plan. One wrong production forecast can turn your most anticipated release into a cash flow headache. The difference between a predictable profit center and an expensive guessing game comes down to one thing: accurate, data-driven forecasting.

If you’re like most breweries, you’re basing your seasonal beer forecasting on gut feelings, “last year plus 20%,” and spreadsheets that were outdated before the first malt was milled.

It’s time to trade hunches for history.

Why Seasonal Beer Forecasting is Harder Than Core Beer Planning

Limited Data Window

Core beers are blessed with consistent sales patterns. They’re steady across months, years and markets. Seasonal beers, on the other hand, have a much shorter sales lifespan, typically lasting 6–8 weeks, and are released only once a year. That tiny window makes patterns harder to identify and forecasting accuracy trickier to achieve.

Add in wildcards like weather, shifting holiday dates and market saturation, and even experienced planners struggle to interpret trends. One unusually warm fall can flatten Oktoberfest sales; one cold spring can stall your summer launch. A pandemic, a new distributor or a viral TikTok trend can completely overhaul your entire model overnight.

Compressed Brewing Timeline

Seasonals operate on a brutal clock. Miss the brew window, and you miss the entire season. You can’t “brew more later” like you might with a core brand. The timing is the product. Specialty ingredients, holiday packaging and tank scheduling create rigid dependencies that don’t forgive delays.

By the time you realize you underestimated production, it’s already too late to brew more. When you recognize you overproduced, the season’s over, and you’re eating cold storage costs.

Variables That Can Wreck a Forecast

Beyond timing, there’s a maze of factors influencing demand, including:

- Weather patterns: Warm fall? Oktoberfest stalls.

- Calendar shifts: Thanksgiving early or late?

- Competitive landscape: How many pumpkin beers hit shelves this year?

- Distribution expansion: Did you open new markets or states?

- Consumer trends: Is the market chasing pastry stouts or crisp lagers?

- Brand momentum: Are you growing, stable or just surviving?

- Events and festivals: Are you brewing around local beer weeks or GABF timing?

Every one of these variables influences your seasonal strategy, and none of them fit neatly into a spreadsheet.

The Cost of Getting It Wrong

Running out of your seasonal brews early means direct revenue loss, but that’s only part of the equation. You’re also missing the highest-margin pints and six-packs your taproom and distributors could have sold for weeks.

Underproduction equals missed momentum, leading to:

- Lost sales when demand exceeds supply

- Frustrated distributors who can’t fill orders

- Disappointed consumers who remember you as “always sold out”

- Missed PR opportunities — you can’t capitalize on buzz if you’re tapped out

Competitors with better forecasting end up owning the shelf space you couldn’t fill.

The flip side is just as ugly. Cases of beer sitting in the cooler long after the season fades. That unsold inventory eats your margins through:

- Tied-up capital in packaging and raw materials

- Cold storage costs for beer you can’t move

- Liquidation pricing that erodes brand value

- Dumped kegs that destroy profit outright

Seasonal beer isn’t wine; it doesn’t age gracefully. A pumpkin ale in January isn’t “vintage,” it’s stale.

The Strategic Costs

Poor forecasting not only hurts sales but also affects every department. Production teams stop trusting the schedule. Marketing wastes budget on beers that aren’t available (or won’t move). Leadership loses confidence in data, which leads back to “gut feel” planning.

Rinse. Lather. Repeat.

The good news? Seasonal beer forecasting isn’t a lost cause. It simply requires structure, discipline and data you can actually use.

Build a Better Seasonal Forecast

1. Start with Data Hygiene

Forecasting accuracy begins with clean data. Audit your historical sales records for completeness and consistency. Are your SKUs properly labeled? Are past anomalies (like pandemic disruptions or distributor changes) clearly documented?

Key steps include:

- Cleansing sales data and tagging seasonals by year and category (fall, winter, spring, summer)

- Establishing a comparable year-over-year reporting framework

- Documenting variables like weather, promotions and distribution shifts

Clean data isn’t glamorous, but it’s what turns your forecasting model from guesswork into science.

2. Develop a Repeatable Forecasting Methodology

Once your data is clean, build a forecasting model tailored to your brewery’s size, product mix and growth trajectory. Consider:

- Which base forecast model fits your history (trend-adjusted, moving average or growth-targeted)?

- How much weight should you give to sales team input versus actuals?

- How will you adjust for new markets or packaging formats?

- What scenarios will you plan for (conservative, moderate, aggressive)?

Then set clear decision rules, such as when to commit to a batch size, when to pivot, and how to split volumes between draft, packaged and distribution channels.

3. Implement Real-Time Monitoring

Forecasts are only as good as the feedback loop. Real-time, sell-through tracking enables breweries to course-correct before a miss becomes a significant issue.

With the right system, you can:

- See daily performance by channel, SKU or format

- Define alert thresholds for accelerated sell-through

- Track taproom pours separately from wholesale sales

- Establish decision points for brewing another batch (or cutting off production)

This kind of responsiveness turns seasonal brewing into a strategic exercise rather than a high-stakes gamble.

4. Close the Loop Post-Season

After the season ends, the learning begins. Conduct a forecast vs. actual analysis to pinpoint what worked and what didn’t. Measure accuracy (within 10%? 20%?), note any external influences, and then update your forecasting model accordingly.

Ask:

- Which seasonals sold out too fast?

- Which lingered too long?

- Were assumptions about distribution or consumer trends accurate?

Sharing these insights with your production and sales teams builds confidence and keeps your seasonal program evolving intelligently.

Brewery ERP: Where Data Meets Brew-Day Decisions

Spreadsheets can’t handle the complexity of seasonal beer forecasting. They’re static, siloed and slow. Fast-moving breweries need the opposite.

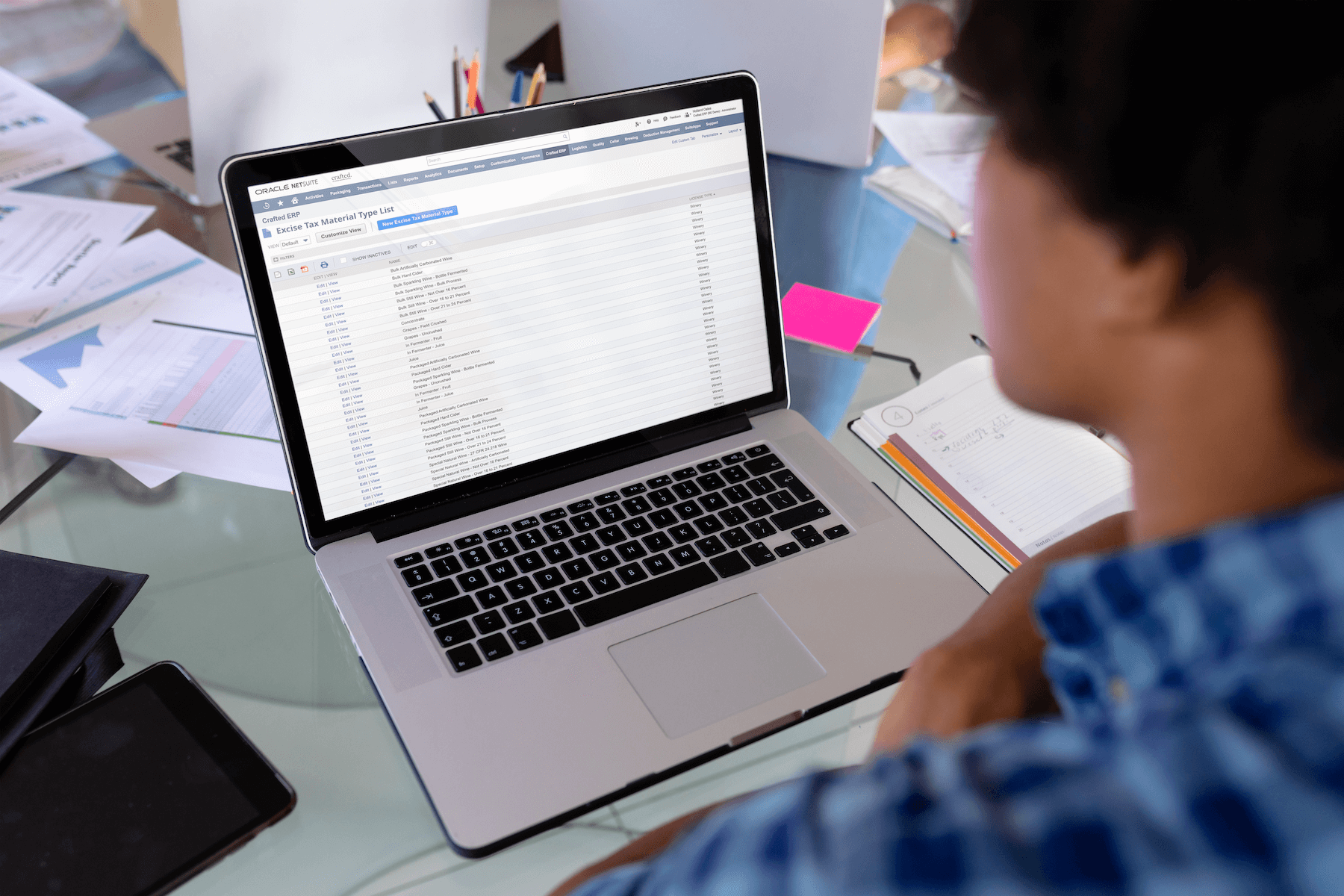

An integrated ERP system, such as Crafted ERP Brewery Edition, provides breweries with a real-time command center for forecasting. It transforms data into actionable intelligence:

- Historical sales tracking by beer, channel and time frame

- Trend and cohort analysis for multi-year comparison

- Real-time inventory visibility across taproom, distribution and retail

- Production planning tools tied directly to forecast data

- Mobile access for on-the-go decision-making from the brewhouse or beer fest

With those capabilities, brewers can instantly see how this year’s Oktoberfest is performing compared to the past three. If sales are tracking 15% higher by week four, they can decide whether it’s worth brewing a short final run before the window closes.

This isn’t generic ERP reporting. It’s purpose-built brewery intelligence that understands your tank turns, packaging formats and seasonal release rhythm.

Turning Seasonals from Gamble to Growth Engine

The perfect seasonal that sells out just as the next one arrives isn’t luck. It’s data discipline.

Breweries that master seasonal beer forecasting:

- Plan production confidently based on historical trends

- Balance taproom and distribution inventory in real time

- Maximize margins by avoiding both sell-outs and excess

- Build brand loyalty by meeting demand consistently

As consumer preferences evolve and shelf space gets tighter, forecasting accuracy becomes oxygen.

With Crafted ERP Brewery Edition, you can:

- Quickly access years of historical seasonal sales data

- Track live sell-through and taproom performance

- Use AI-enabled tools to identify best sellers vs. brews you can lose

- Integrate production planning directly with forecasts

- Adjust brew schedules on the fly, based on real-time data

So next time someone suggests “just brewing a little extra,” smile, pour them a pint, and pull up your Crafted dashboard instead.

While others are crossing fingers, you’ll be gaining profitability. Ready to make next season’s batch your best forecast yet? Contact us to brew smarter.