Barrel programs represent some of the highest-value inventory inside any winery, yet they’re often tracked with tools that can’t keep up. A single barrel can hold $2,000–$10,000 of aging wine, plus $800–$2,500 in cooperage costs, which means a cellar with 1,500 barrels is essentially a multimillion-dollar warehouse of liquid inventory quietly accruing value (or risk) in the dark.

Yet at most wineries, barrel tracking happens with a spreadsheet, a clipboard or the collective memory of whoever “usually knows where the 2022 Cab lives.”

This is how barrels go missing. This is how work-in-process values drift out of sync with financials. And this is how wineries reach a point at which physical counts show a 5–10% variance. Not because barrels walked away, but because systems weren’t built to keep up with the complexity.

Wineries using purpose-built barrel tracking within a modern ERP system operate with real-time visibility, audit-ready accuracy, and complete confidence in what’s aging where, what it’s worth, and what needs attention next.

How Much Value is Stored in Your Barrel Program?

Most wineries underestimate the financial weight of their barrel inventory. Each barrel holds a meaningful portion of future revenue, and a medium-sized cellar can store millions of dollars’ worth of aging wine. When teams can’t see what’s aging where or how value changes over time, financial reporting becomes more difficult, planning becomes guesswork, and audits become stressful.

Once a winery reaches a specific production volume, barrel tracking becomes a mission-critical workflow that manual tools can’t support well.

Why Does Barrel Tracking Become More Complex as a Winery Scales?

Barrels move constantly, and every movement introduces an opportunity for error. They’re filled, topped, racked, blended, moved between rows, transferred between facilities, and reassigned to new lots. In a single week, dozens of transactions can occur that change a barrel’s location, value or readiness.

Spreadsheets weren’t designed for this level of activity. They don’t update in real time, break when multiple people edit them, and rely heavily on tribal knowledge. Spreadsheets introduce drift, delays and inconsistencies as teams grow and operations become more complex.

This drift shows up as:

- Barrel counts that don’t match physical inventory

- Missing barrels discovered months after the fact

- Work-in-process values that don’t reflect reality

- Cellar teams wasting hours searching for the right barrels

- Lost traceability in wine blend management when barrels are combined

- Production delays during bottling

Manual tools can’t keep up when wineries scale past a few hundred barrels.

How does operating across multiple sites make barrel tracking harder?

Multiple facilities multiply complexity. Australia’s Tamburlaine Organic Wines experienced this firsthand when they acquired a second winery in the Orange region, complementing their original site in the Hunter Valley. The expansion increased production capacity but also brought with it the challenges of multi-location winery operations, with barrel, packaging and supply chain activities now spanning two geographically distant locations.

Before implementing Crafted ERP, Tamburlaine used several disconnected systems. Staff spent excessive time validating data, reconciling inventory lists and chasing errors. As Managing Director Mark Davidson explained, the status quo involved “cobbling the system together” with tools that couldn’t provide the transparency needed for a vertically integrated producer.

Tamburlaine needed accurate, real-time visibility into inventory and production across both sites, not a patchwork of spreadsheets and siloed tools.

Why do barrel counts drift in spreadsheet-based systems?

Manual systems break down for predictable reasons:

- Too many moving parts: Barrel status changes often. A single update missed on a clipboard can create weeks of confusion.

- No real-time updates: Cellar activity happens on the floor, but spreadsheets live on an office computer.

- Version control issues: Multiple people editing the same document leads to overwrites and conflicting versions.

- Limited historical tracking: Teams can’t easily see topping history, tasting notes, evaporation losses or past blends.

- No guardrails: Spreadsheets can’t prevent impossible entries, like duplicate barrel IDs or barrels “living” in two places at once.

As seen across every winery that outgrows spreadsheets, knowledge gets locked in people rather than systems, creating significant operational vulnerability.

That fragility compounds in barrel programs.

What Operational Risks Come from Inaccurate Barrel Tracking?

When wineries don’t know precisely where each barrel is or what’s inside it, several problems emerge:

- Production delays during racking, topping or bottling

- Quality risks from missed topping or overlooked barrels

- Wasted labor spent searching for barrels

- Difficulty assembling lots for blending

- Bottlenecks during audits or compliance reviews

- Inaccurate revaluation of wine aging in a barrel

These issues can slow production workflows, erode margins and undermine confidence in the data used to run the business.

Tamburlaine emphasized this point during their software evaluation. As an organic and biodynamic producer, they needed precise, auditable, traceable data across every step of production. Minor errors quickly become costly for wineries subject to certification requirements.

How does barrel tracking software answer wine industry challenges?

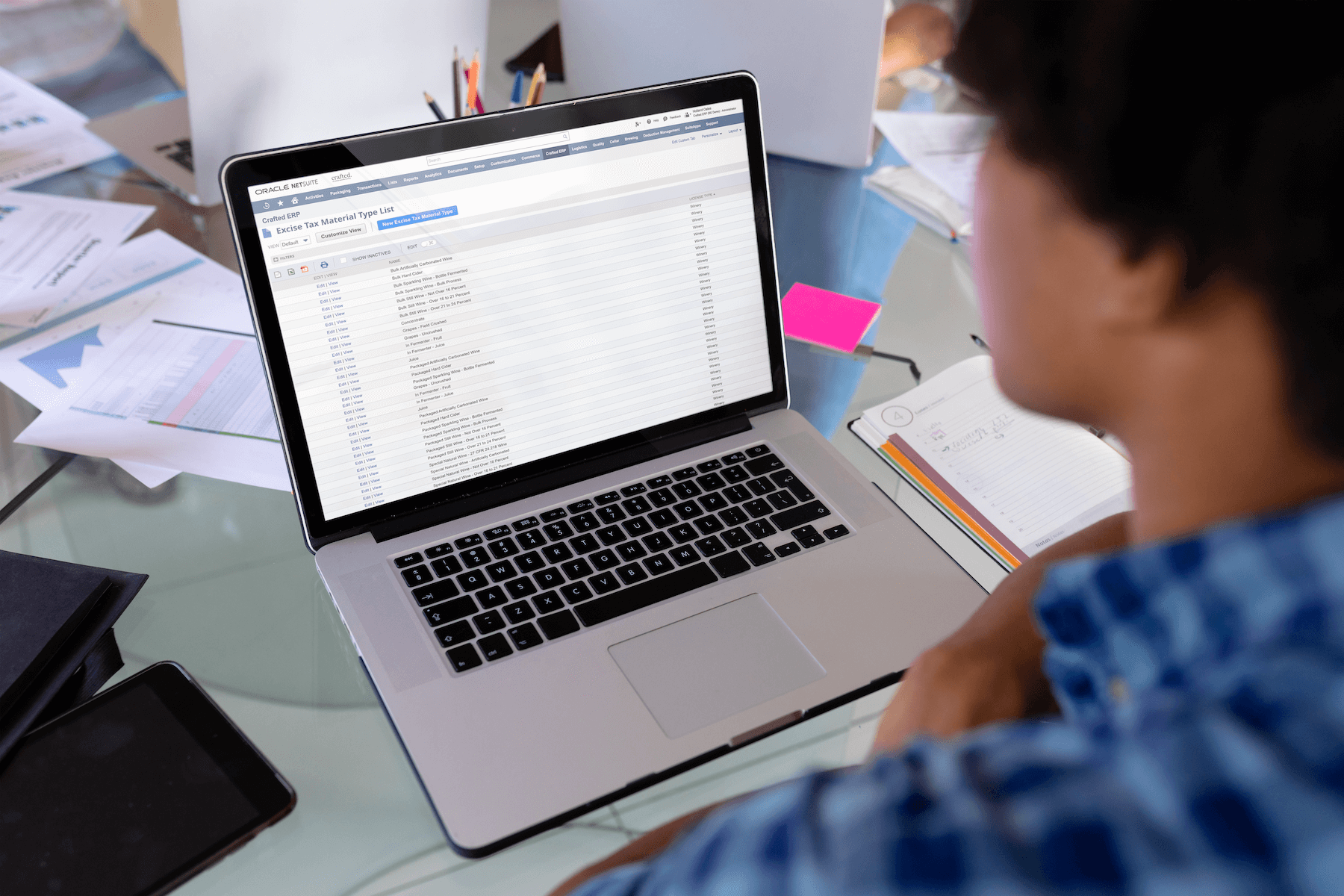

Winery ERP software tracks each barrel as an individual asset. This creates a single source of truth across cellar, production and finance teams.

That visibility includes:

- Barrel ID and scan-based tracking

- Location down to warehouse, row and position

- Contents, fill date, vintage and chemistry

- Current volume and evaporation trends

- Status (empty, full, in use, needs topping, ready for bottling)

- Complete movement history

- Automatic value calculation based on aging

Every update occurs in real time, so teams always see accurate inventory levels.

What Operations Can Wineries Automate With ERP-Based Barrel Tracking?

Automation reduces the most common sources of error. With an integrated system, wineries can:

- Send alerts when barrels need topping

- Flag aging milestones and tasting schedules

- Update barrel status automatically during rackings and blends

- Trigger revaluation based on time in barrel

- Track QA results and sensory notes directly in the system

- Plan capacity based on real-time barrel availability

Tamburlaine saw the value of this automation immediately. Their leadership team noted that Crafted reduces unnecessary clerical work and helps staff “work smarter, not harder” as operations grow. Automation gave them the visibility and efficiency they needed to manage two sites with confidence.

How Does Better Barrel Tracking Improve Financial Accuracy?

Barrel inventory ties directly to financial reporting. When WIP values drift, month-end close slows down and COGS becomes unreliable.

ERP-based barrel tracking supports financial accuracy through:

- Real-time WIP valuation

- Automatic revaluation as wine ages

- Accurate cost allocation for barrel usage

- Faster reconciliation during month-end

- A complete audit trail of every movement

For wineries with certifications like Tamburlaine, this audit-ready transparency isn’t optional. It’s part of maintaining winery compliance and protecting brand integrity.

How does reliable barrel data improve forecasting and planning?

Accurate barrel tracking strengthens forecasting in several ways:

- Barrel purchasing becomes data-driven

- Harvest planning aligns with real capacity

- Cash flow projections incorporate real WIP values

- Retirement schedules for barrels are easier to manage

- Production timelines become more predictable

Reliable data helps leadership move from reactive planning to strategic decision-making.

What Does Modern Winery Barrel Management Look Like in Practice?

A data-driven barrel program has several defining characteristics:

- Teams know precisely where every barrel is

- Work orders automatically update barrel status

- Financials reflect actual inventory value

- Quality tasks are scheduled and tracked

- Cross-facility visibility reduces duplication and delay

Tamburlaine’s implementation reflects this shift. With operations in the Hunter Valley and Orange, they needed unified visibility across production, packaging, compliance and inventory. Crafted provided that cohesion, giving the winery a connected workflow that supports growth and complexity without adding manual burden.

What Should Wineries Do Next If Barrel Tracking Feels Difficult?

If barrel inventory feels hard to manage, that’s a signal your workflows have outgrown manual tools. Start by assessing where inconsistencies appear:

- Do physical counts match system counts?

- Can staff find specific barrels quickly?

- Do cellar and finance teams share the same data?

- Do topping and tasting tasks slip through the cracks?

- Does month-end close get complicated by WIP uncertainty?

If any of these issues sound familiar, it’s time to explore winery barrel management that fits your operation’s scale.

Ready to see barrel tracking that finally keeps up with your production?

Crafted ERP Winery Software provides wineries with real-time barrel visibility, warehouse mapping, automated alerts and seamless integration with production and financial data. It’s built for how modern wineries age, track and value their most important assets.

Curious to see how this works in practice, including how a multi-site producer can gain transparency and cohesion? Visit us at the Unified Wine & Grape Symposium, January 27-29, at Booth A2700 or set up a strategic call anytime. Schedule your personalized consultation by filling out our form here.