Blending is where winemaking becomes both an art and a process. It’s how wineries create signature profiles, maintain consistency across vintages, and deliver products that align with market expectations.

But while the art depends on the winemaker’s palate, the process depends on data. Without accurate lot traceability, barrel tracking, trial documentation and cost visibility, even the most experienced winemaker can struggle to reproduce a successful blend or maintain profit margins.

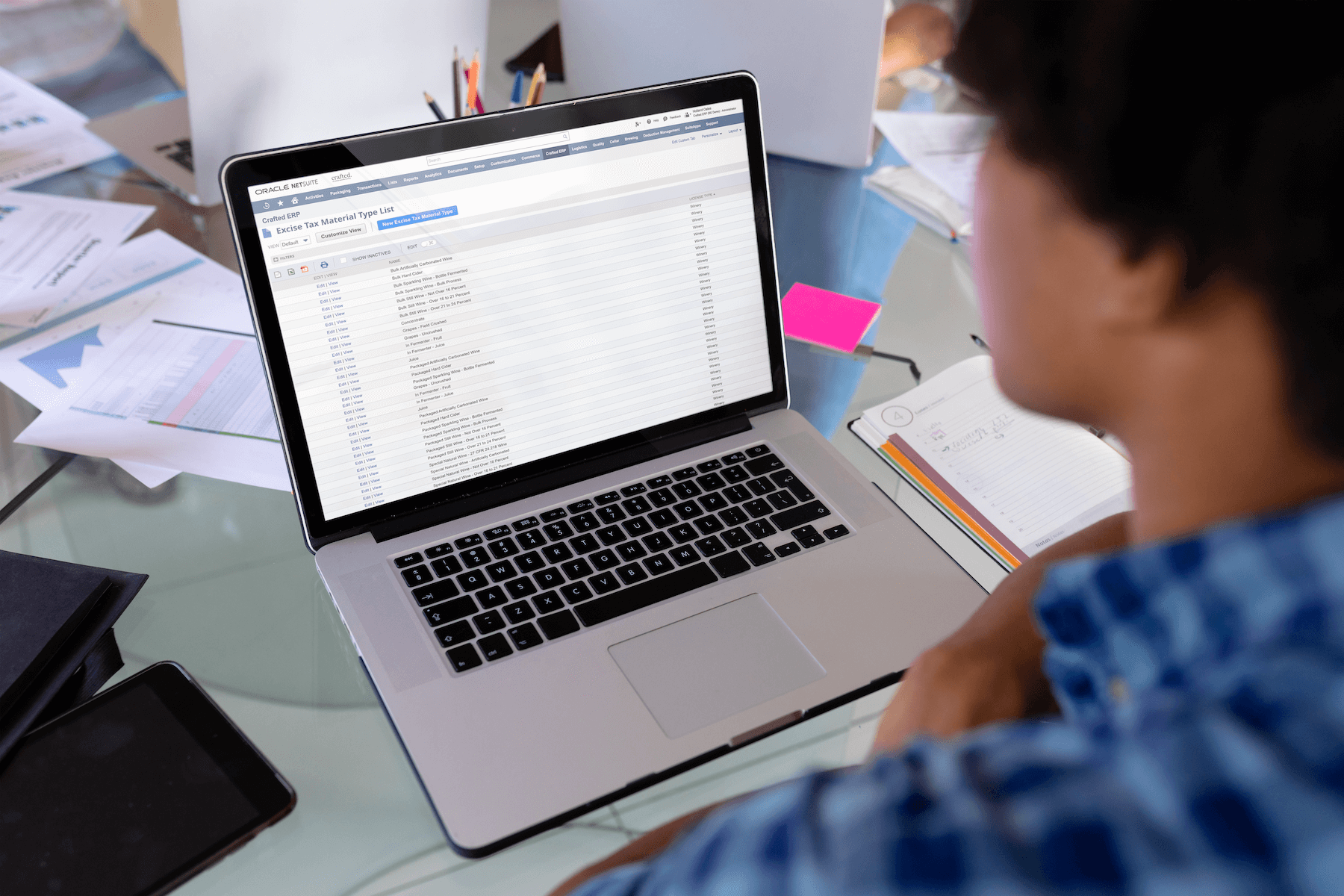

Modern winery business management software bridges that gap, amplifying your artistry with data-driven accuracy. It turns your winemaking process into a repeatable, compliant and cost-efficient craft that scales as your production grows.

Why Winemaking Demands More Than a Spreadsheet

Every blend is the result of dozens of moving parts: vineyard variability, fruit chemistry, oak treatment, storage conditions and the personal touch of the winemaker. For any winery working with multiple varietals or vineyard sources, managing that data manually becomes a bottleneck.

Take a winery with 40 Cabernet Sauvignon lots from a single harvest. The fruit may come from five different growers, each with distinct vineyard conditions and pick dates. Add variations in fermentation, aging and oak treatment, and the complexity multiplies.

A winemaker has to know:

- Which lots meet the desired flavor and chemistry profiles

- What percentages to use to maintain varietal labeling compliance

- How each component affects cost per gallon and final retail price

Tracking all that with notebooks, spreadsheets and other disparate systems works…until it doesn’t. As soon as teams expand or lots scale into the hundreds, manual systems and multiple sources of truth make it hard to maintain accuracy, consistency and accountability.

A centralized winery production system keeps the data, not the memory, doing the heavy lifting. When everything from brix levels to tannin structure lives in one place, winemakers can spend less time searching for information and more time refining the blend itself.

Building a Solid Blend Management Foundation

A well-managed blend isn’t just a record — it’s a control system for quality and compliance. It defines the pedigree, tracks changes, and provides a framework for scaling production without losing the sensory intent.

Modern winery management systems allow winemakers to:

- Create master blends with varietal percentages and linked lots

- Record sensory notes and tasting feedback directly in the system

- Track trial blends and iterations for continuous improvement

- Scale production up or down while maintaining ratios

- Protect proprietary blends with access control

Each blend becomes a living document tied to its real-world components. For wineries producing across multiple varietals or price tiers, this provides a foundation for consistency and traceability, which is essential for brand protection and audit readiness.

Best Practices for Wine Blend Management

- Document trial blends immediately. Don’t rely on memory — log every combination while it’s fresh.

- Tag sensory profiles. Record tasting notes, aroma descriptors and intended market positioning.

- Capture the “why,” not just the “what.” Include rationale behind blending decisions to preserve institutional knowledge.

- Link blends to lots. Tie each batch to its lot source for traceability and compliance.

- Use version control. Track every iteration so improvements don’t erase the original.

- Protect proprietary data. Secure your winemaking IP with controlled team access.

Crafted’s blend management tools let wineries reference previous assemblages, adapt to vintage variations, and evaluate the cost, inventory and compliance impact before finalizing.

Lot Traceability: Knowing Every Drop

Every wine is the sum of its lots — and every lot has a story to tell. From vineyard block to barrel, traceability protects both quality and compliance.

With lot traceability software, wineries can:

- See the full history of each lot (source, harvest, fermentation, aging)

- Document the complete pedigree from parent wines through final blend

- Track quality metrics such as pH, TA, alcohol and phenolics

- Confirm label integrity for varietal and appellation requirements

- Prevent blending errors through validation checks

Crafted’s lot traceability features show exactly what you have, where it is and how it fits into your winemaking strategy — without cross-referencing logbooks or sticky notes. Barrel-to-blend traceability also safeguards winery compliance with varietal and appellation requirements, while real-time lot validation helps prevent blending errors before they happen.

In other words, you’ll spend less time hunting down details and more time perfecting what’s in the glass.

Understanding the Economics of Wine Blend Management

Behind every great wine is a spreadsheet…or at least there used to be. But accurate costing is one of the most challenging parts of winemaking, especially when each component has a different cost basis.

A batch might combine:

- Estate-grown fruit at $4,000/ton

- Purchased fruit at $1,800/ton

- Varying oak treatments, aging time and production labor

Without real-time costing, winemakers are left guessing whether their 60% Cab / 40% Merlot blend should retail at $35 or $50. That’s why cost tracking can’t be separate from production data.

With Crafted, costing happens automatically. The system calculates costs across all input — fruit, labor, overhead, packaging — and shows how every blend scenario affects your margins before you commit to a single gallon.

“As our various farming-related bills come in, we code them to the specific vineyard and block,” says Quinn Sheridan, supply chain analyst at Long Meadow Ranch. “When the time comes to produce our case goods, we already know what our fruit and overhead costs were, allowing us to have accurate cost tracking from start to finish.”

That means pricing decisions are made with data, not instinct, making profitability intentional.

Scaling Production Without Losing Control

Winery growth often means managing complexity at scale. More sites, brands and people equal more opportunities for miscommunication and inefficiency.

Crafted customer Bear Creek Winery is a clear example. Based in Lodi, California, the sixth-largest family-owned U.S. winery manages over 7,000 acres of vineyards and produces more than 11 million gallons of wine across estate, private-label and custom crush programs. For years, its bulk wine and case goods businesses ran on different systems, creating inefficiencies and accounting headaches.

“We had an internally developed program that reached its peak in performance and abilities,” said Kevin Murphy, controller at Bear Creek Winery. “Crafted replaced that program completely and integrated better with other systems to improve the information flow across multiple departments.”

When Bear Creek adopted Crafted, the change eliminated manual reconciliations, enabled automated reporting, and allowed the winery to manage its diverse operations with real-time visibility.

“It’s night and day from before. Everything is in real time, and that’s my favorite thing,” added Tom Rappe, global business management director. “It’s more cohesive, the data is always up to date, and I love having all the details of our customer relationships right at my fingertips.”

For Bear Creek, scalability meant integration. A single source of truth that connects inventory, costing and compliance across brands. The result: smoother operations, fewer data silos, and the confidence to grow without losing oversight.

Best Practices for Scaling

- Centralize all blend and lot data in one system

- Standardize workflows across teams and facilities

- Train new staff with documented production procedures

- Use secure access controls to protect blend IP

When every department sees the same data, production decisions are made faster and are more reliable. That’s the real power of moving from isolated systems to integrated winery ERP software.

Shifting from Spreadsheets to Systems

When production grows, more people touch the same data, and regulators or distributors start asking tougher questions, you’ve outgrown spreadsheets and intuition. What worked at 5,000 cases starts to crack at 25,000. The moment you need consistency across vintages, visibility across sites and traceability across every drop, it’s time to trade patchwork processes for ERP.

Most winemakers have lived this contrast. Manual processes that once felt manageable — trial blends scattered across notebooks and Excel sheets, lot tracking done by hand, costing calculated after production, and compliance documentation pieced together from multiple sources — become unsustainable as production scales.

An integrated ERP system centralizes everything: blend formulations with full version control, real-time inventory showing chemistry data and exact locations, automated costing tied to makeup, audit-ready compliance reporting, and shared institutional knowledge accessible across your entire team. The shift isn’t just about efficiency — it’s about transforming fragmented data into actionable intelligence.

Long Meadow Ranch Vice President of Finance Brett Pinkin says, “Crafted ERP is cloud-based and holistic. It provides accurate, actionable insights for products made years before they’re sold.”

With data doing the heavy lifting, your winemaking team can stay focused on creating extraordinary wines that reflect your vineyard, your vision and your values. This integration is especially critical for multi-location winery operations, where managing multiple brands, contracts and production sites requires seamless coordination to reduce errors and enable sustainable growth.

The Best Blends Start With Better Data

In winemaking, consistency is the truest measure of mastery. The best wineries don’t leave that to luck. Blending will always depend on the winemaker’s instincts, but data ensures those instincts lead to consistent, profitable results. The more wineries understand their lots, costs and makeup, the easier it becomes to make decisions that balance artistry with business outcomes.

Winery management systems make the winemaker’s role more powerful. They preserve knowledge, eliminate guesswork and provide the operational clarity needed to grow with confidence.

As competition intensifies and consumer expectations rise, wineries with better data make better wines, are more profitable, more sustainable and more confident.

Blend It. Track It. Perfect It. Protect your wine and perfect your process with Crafted ERP. Let’s build your next great vintage together, powered by active intelligence embedded in your data. Ready to see what happens when your instinct meets insights?