Running a winery means managing fruit from multiple vineyard blocks, overseeing barrel programs across locations, coordinating bottling schedules, updating TTB reports, and keeping tasting room, DTC and wholesale sales in sync.

Traditional winemaking craftsmanship stays consistent, but the operational workload behind it has grown more complex and data-heavy. Today’s wineries are juggling:

- Vintage-specific inventory

- Multi-year production cycles

- Increasing compliance requirements

- Expanding sales channels

- Rising expectations for cost accuracy and traceability

Most wineries eventually hit the breaking point with spreadsheets and standalone tools. Inventory counts stop matching physical reality, and month-end close stretches from days into weeks. Compliance reporting consumes more staff time each month, while financial visibility lags further behind operations. Leadership is left to make critical decisions without real-time numbers.

Purpose-built winery ERP software changes that. It connects production, inventory, compliance, sales and financials on a single, unified platform so teams can trust and work from the same data.

Why Do Wineries Outgrow Spreadsheets and Manual Tools?

Every winery reaches a tipping point where manual systems can’t keep pace with operational demands. For some, it happens at 10,000 cases. For others, 50,000. The volume varies, but the pattern doesn’t — spreadsheets lose accuracy, data compilation becomes a bottleneck, and leadership starts making decisions based on outdated information.

The operational costs compound quickly:

- Lost time: Teams spend hours each month reconciling production records, inventory counts and financial entries that should match automatically.

- Compliance pressure: TTB reporting requires complete accuracy. Gathering data across different sources creates delays and increases risk. Each additional system adds another point at which volumes, gains and losses can fall out of sync.

- Unreliable cost visibility: Without integrated costing, pricing decisions depend on estimates and assumptions instead of true, up-to-date cost data.

- Limited strategic insight: Leadership cannot plan capital investments, new plantings or distribution expansion without timely data. Strategic planning becomes reactive instead of anchored in clear performance and profitability trends.

- Restricted growth: As volumes increase, manual processes break down. Expanding to multiple locations or adding new brands becomes difficult without structured systems. At this stage, system limitations — not market demand — often dictate how fast the winery can grow.

For many wineries, this is the point where questions like “What did this wine actually cost to produce?” or “How much saleable inventory do we have by vintage?” become hard to answer quickly.

Winery ERP software solves this by giving every team access to the same real-time data. Instead of relying on individual memory or manual reconciliation, a centralized system becomes the single source of truth for all operational information.

What is Winery ERP Software?

Winery ERP software connects all core winery operations in a single system with real-time visibility. It tracks every stage of production, maintains barrel and lot data, manages cost updates, automates compliance reporting, and delivers financial visibility across the business.

Winery ERP is designed to fit the way wineries operate by supporting:

- Long production cycles

- Complex cost structures

- Lot-level traceability

- TTB and state compliance

- Multi-location inventory

- Seasonal and vintage variability

It creates a single source of truth that replaces disconnected tools and manual reconciliation. This means any change in production or inventory automatically updates costing, compliance data and downstream financial reports.

What Features Should Winery ERP Software Include?

Winery ERP software needs to handle operations that generic business tools simply can’t — barrel aging that spans years, lot traceability from vineyard block to customer, TTB reporting that demands perfect accuracy, and profitability analysis by vintage and channel.

The following capabilities distinguish purpose-built winery systems from adapted manufacturing software. These aren’t nice-to-have features — they’re the operational foundation that enables confident decision-making, profitability and growth.

1. Vineyard and Production Management

- Production scheduling from crush to bottling

- Fermentation and lot tracking

- Tank and barrel capacity management

- Work order assignments and quality checks

These tools keep production data accurate, timely and visible to both winemaking and back-office teams.

2. Blend and Recipe Management

Blends rely on both creativity and data discipline. Winery ERP keeps blend details structured so you can repeat successful profiles and protect margins.

- Digital recipe library

- Version control for blend trials

- Component-level costing

- Sensory notes and approval workflows

Effective wine blend management requires capturing trials, linking lots and tracking costs in one place. Your best practices underscore the critical importance of consistency and traceability.

3. Barrel and Maturation Management

Accurate barrel tracking protects inventory value and COGS accuracy.

- Status and location visibility

- Topping schedules

- Automated barrel fills, transfers and updates

- Age-based revaluation

When operations scale, barrel management becomes a core financial lever. Winery ERP software links barrel movements directly to inventory valuation, so aging decisions and storage choices are reflected in your financials.

4. Inventory and Lot Traceability

Complete, real-time traceability supports quality control and recall readiness.

- Lot-level tracking from vineyard to bottle

- Multi-warehouse visibility

- Cycle counting

- FEFO logic and inventory rotation

This eliminates manual cross-referencing and mismatched counts. It also gives you immediate answers to questions like “Which customers received wine from this lot?” or “Where is this vintage stored today?”

5. Compliance and Regulatory Reporting

Winery compliance becomes a structured, predictable workflow. Instead of rebuilding reports each month, wineries can rely on standardized, repeatable processes.

- Automated TTB forms

- State shipping compliance

- Label approvals and COLA tracking

- Excise tax support

- Audit-ready documentation

This reduces time spent on data collection, lowers error rates, and improves record accuracy for regulatory reviews.

6. Financial Management and Cost Tracking

Integrated financials provide reliable visibility.

- Real-time COGS

- AP/AR workflows

- Budget vs. actual

- Multi-entity accounting

- Profitability by SKU, channel and customer

These tools provide the foundation for strategic decision-making. Leadership can quickly identify which wines, formats and channels deliver the highest margins.

7. Sales, Distribution and DTC Management

Sales activity connects to actual inventory and compliance needs.

- Order management

- Channel-based pricing

- Available-to-promise inventory

- CRM and customer insights

- E-commerce integrations

These capabilities help avoid over-allocations, prevent stockouts, and keep customer promises aligned with real inventory levels.

8. Reporting and Analytics

Dashboards and reports highlight performance clearly.

- Production efficiency

- Yield and loss analysis

- Margin visibility

- Inventory valuation and turn rates

- Executive summaries

Better information leads to better decisions. When each department can see its own KPIs alongside financial outcomes, course corrections become faster and more precise.

How are Leading Wineries Using ERP to Improve Operations?

Growing wineries use ERP to gain real-time visibility into production, costs and inventory, enabling them to scale with confidence.

Tamburlaine Organic Wines

Tamburlaine needed better production control and cost visibility as it expanded. Crafted ERP unified production, sales and financials, improving accuracy and operational efficiency.

With a single platform, the team can see how vineyard decisions, cellar operations and sales activity affect overall performance.

Long Meadow Ranch

Cost tracking once required manual compilation. Now the team codes farming-related bills directly to vineyard and block records, gaining accurate cost visibility from start to finish.

This shift enabled Long Meadow Ranch to price wines with greater confidence and understand profitability by block, vintage and program.

Bear Creek Winery

With more than 7,000 acres and multiple business lines, Bear Creek needed a unified data platform to manage its growing contract operations. Before ERP, production and case goods lived in separate systems. After moving to a single platform, reporting improved, reconciliations dropped, and teams finally had 360-degree visibility. “Everything is in real time… the data is always up to date,” leadership shared.

These examples reflect a consistent theme: wineries operate more efficiently when the entire business has access to the same information simultaneously. It also shows that ERP is not just a financial tool; it’s the operational backbone that supports growth.

Why Winery ERP Matters More Now

Most wineries don’t implement ERP because they love software — they implement it because their current systems can’t keep pace with operational demands. Compliance requirements expand each year. Distributor and retail partners expect faster response times and complete traceability. Multi-location winery operations create complexity that spreadsheets can’t handle at scale. Margin pressure demands cost visibility that manual systems can’t deliver accurately or quickly enough.

Businesses investing in winery ERP software aren’t abandoning their winemaking craft; they recognize that operational excellence enables that craft to scale profitably. Real-time data becomes the foundation for better decisions.

The question isn’t whether these operational capabilities matter. It’s whether your current systems support the winery you’re building or limit it.

What to Do When Evaluating Winery ERP Software

If your winery struggles with outdated systems, slow reporting or limited visibility, start with an honest assessment of your current processes. Look for where your current systems break down and try to identify:

- Where does data live?

- Which workflows rely on manual updates?

- What decisions are slowed or blocked by missing information?

- Which departments lack real-time visibility to operate effectively?

Define what success should look like, then explore solutions built specifically for wine production, barrel and inventory management, direct-to-consumer sales, and regulatory compliance. Capture these needs as requirements so you can compare ERP vendors against clear, winery-specific criteria.

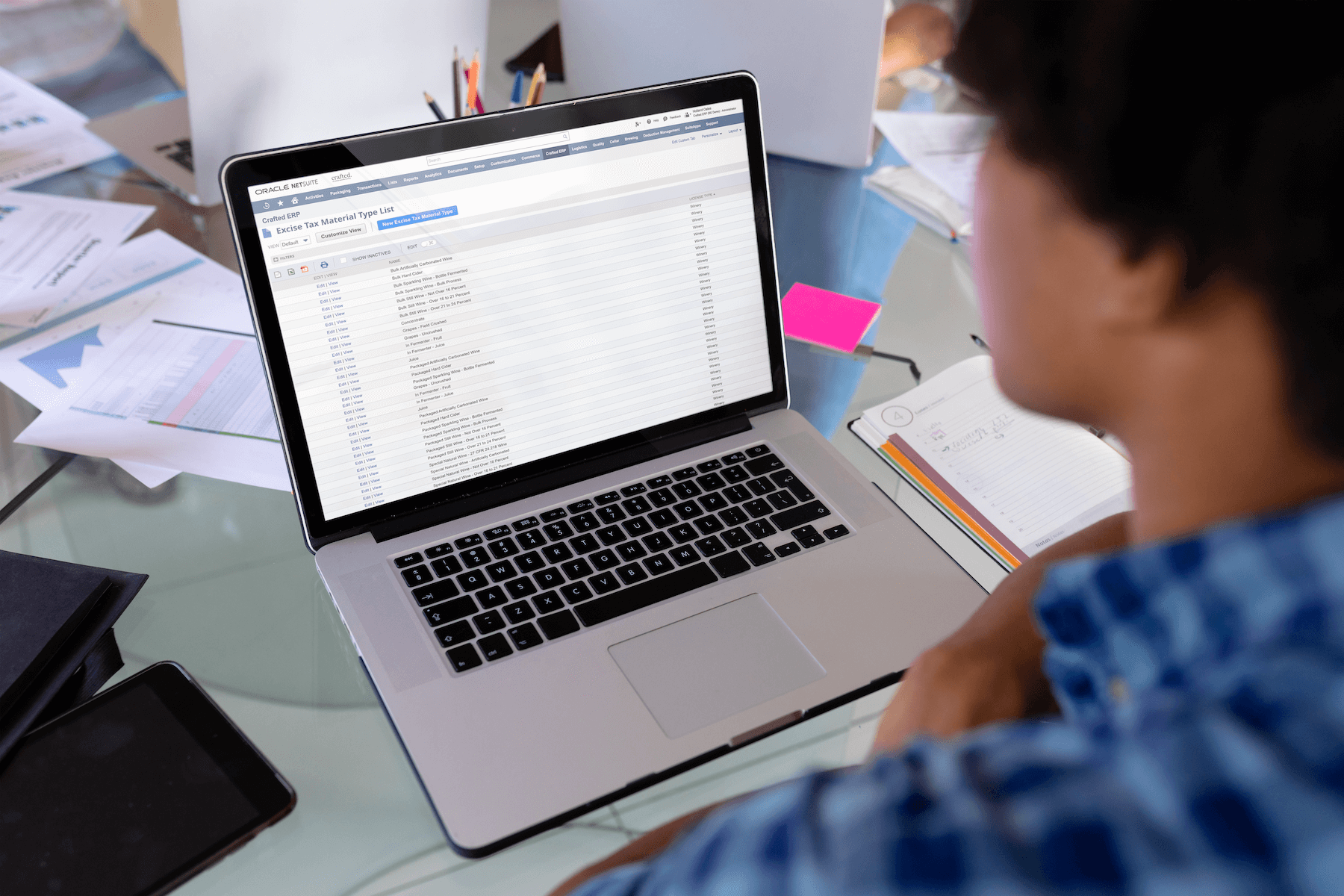

How Can You See Winery ERP in Action with Crafted?

If you want a clearer view of what a connected winery looks like in practice, visit the Crafted team at the Unified Wine & Grape Symposium at Booth A2700.

We’ll walk you through how a purpose-built winery ERP software supports production, costing, compliance and financial accuracy on a single platform.

Not attending the trade show? Contact our team to set up a strategic call to see how modern winery operations run on a connected system.

Frequently Asked Questions About Winery ERP Software

What is winery ERP software?

Winery ERP software is a cloud-based business management platform that unifies a winery’s production, inventory, compliance, accounting and sales operations into a single system. ERP stands for Enterprise Resource Planning. In a winery context, it replaces the disconnected combination of spreadsheets, standalone accounting software and production-tracking tools that most wineries rely on early in their growth. A purpose-built winery ERP connects data across every department — from crush operations and blend management to barrel tracking and DTC fulfillment — so teams work from one accurate, real-time source of truth rather than reconciling information across multiple systems.

What does winery ERP software actually do?

Winery ERP software manages the full production lifecycle alongside every business function that supports it, from vineyard and procurement through fermentation, barrel aging, bottling, compliance reporting, inventory management, supply and demand planning, and customer order fulfillment. On the production side, it handles WIP routing, batch logs, tank utilization, blend versioning, label management and automated bills of lading. On the business side, it manages real-time financial reporting, accounts payable, inventory visibility and winery-specific KPIs. The most capable platforms, such as Crafted ERP Winery Edition developed by Doozy Solutions and powered by Oracle NetSuite, also include FEFO lot selection, alternating proprietorship reporting, and integrations with DTC platforms like Commerce7 and Shopify, so that production and commercial operations run in sync.

Why do wineries need industry-specific ERP software instead of a generic platform?

Generic ERP platforms were not designed for the realities of wine production, which means wineries that use them typically spend significant time and money on customizations, workarounds and manual reporting that a purpose-built system handles out of the box. Crush operations, barrel and maturation management, alternating proprietorship reporting and blend costing require functionality that general business software does not natively support. A winery-specific ERP like Crafted ERP Winery Edition, developed by Doozy Solutions with direct input from winemakers and industry veterans, includes these capabilities as standard features, along with pre-configured compliance reporting for the USA, Canada, Australia, Germany and the UK. The result is a shorter implementation timeline, lower total cost of ownership and a system that fits winery workflows rather than forcing workarounds.

How does winery ERP software handle compliance reporting?

Winery ERP software manages the full scope of alcohol beverage compliance obligations, including excise tax reporting, label and license registration tracking, alternating proprietorship reporting, redemption value reporting and 1099 contractor documentation. Month-end reporting is time-consuming and error-prone without a system that tracks the right data throughout production. Winery compliance automation is one of the primary reasons wineries move off spreadsheets and standalone tools. Purpose-built platforms like Crafted ERP Winery Edition include pre-configured compliance reporting for multiple countries and allow wineries to set license renewal reminders, store label approvals, and generate accurate tax reports in real time. As a winery grows to multiple locations or beverage categories, compliance data stays accurate across all entities within the same system.

Can winery ERP software support barrel tracking and aging inventory?

Yes. Robust winery ERP software includes dedicated barrel and maturation management capabilities that provide real-time visibility into every barrel — whether full, empty, on-site or at a third-party storage facility. This is a critical distinction from generic inventory software, which cannot account for the unique workflows involved in barrel fill, harvest, revaluation and warehouse mapping. A platform like Crafted ERP Winery Edition tracks accurate on-site and off-site barrel counts, automates barrel reporting, and integrates barrel aging directly into the production process, reducing the risk of unfulfilled orders, missing inventory and compliance gaps that come with incomplete aging records.

Does winery ERP software scale to multi-location operations?

Winery ERP software built on a modern AI-powered cloud platform scales to support multi-location operations with consolidated financial reporting, intercompany transfers, and inventory visibility across all entities within a single login. Multi-location winery management becomes significantly more complex without a unified system. Teams end up logging into separate software for each facility, manually reconciling data, and losing the real-time visibility that informed decision-making requires. Crafted ERP Winery Edition customers, including Long Meadow Ranch, which operates 8 subsidiaries on the platform, and Ackley Brands, which manages 13 winery and brewery brands across its portfolio, use a single system to maintain standardized processes, consolidated reporting and entity-specific charts of accounts simultaneously.

What should wineries look for when evaluating ERP software?

When evaluating winery ERP software, wineries should prioritize industry-specific functionality, compliance coverage, integration capabilities, and scalability, rather than selecting a general-purpose platform based solely on brand recognition or price. Key functionality to assess includes blend management, barrel tracking, DTC integrations, multi-entity accounting, and pre-configured compliance reporting for the relevant markets. Implementation methodology matters as much as features. A vendor with deep beverage industry experience, such as Doozy Solutions (an Oracle NetSuite 5-Star Partner and official Solution Provider and Solution Developer), brings proprietary, proven implementation methodologies to bear rather than requiring customers to cross their fingers and hope for the best. The result is a platform that both fits the way a winery operates at cutover and also has the flexibility to expand as the business grows.

How does winery ERP software integrate with DTC platforms and other tools?

Winery ERP software integrates with popular DTC platforms and e-commerce tools that wineries rely on, automatically syncing data between systems rather than requiring manual imports and exports. Common integrations include Commerce7 for tasting room and wine club sales and SOVOS ShipCompliant for state-by-state distribution compliance and DTC shipping management. Crafted ERP Winery Edition manages all integrations through the Crafted ERP Connector, which enables continuous, real-time data flow between platforms. Long Meadow Ranch, for example, used the Commerce7 integration to eliminate the manual reconciliation work that had previously required logging in and out of multiple systems across eight entities.

How does winery ERP software handle data security and AI capabilities?

The strongest winery ERP platforms address both through a single architectural decision: what cloud infrastructure they’re built on. Crafted ERP Winery Edition runs on Oracle NetSuite and Oracle Cloud Infrastructure (OCI), which provides defense-in-depth security, data encryption at rest and in transit, continuous threat monitoring, and compliance with ISO/IEC 27001, SOC 1, SOC 2, and SOC 3. That same unified data foundation powers NetSuite’s embedded AI capabilities — including demand forecasting, financial anomaly detection, and intelligent inventory optimization — which deliver reliable results only when production, inventory, compliance and financial data all live in one connected system.

Can winery ERP software support expansion into other beverage categories?

Yes. Wineries that expand into spirits, cider, RTDs or beer don’t need to start over on a new system, provided their ERP platform is built to scale across beverage categories. Crafted ERP BevX is the only multi-category beverage ERP platform, allowing producers to add new license types and production categories within the same instance, with multi-entity accounting, multi-license compliance and consolidated cross-category reporting already built in. For wineries evaluating long-term software fit, the ability to grow into new categories without a second implementation is a meaningful operational and financial advantage.

Last updated: February 27, 2026