Ask any beverage production leader what their biggest fear is, and it isn’t long hours. It’s losing the quality that built their reputation. Growth should mean more fans, not more mistakes. But when scaling feels like choosing between quantity and craft, the stakes couldn’t be higher.

Meanwhile, the day-to-day reality adds to the pressure: missing barrels in the spreadsheet, idle tanks due to scheduling errors, or discrepancies between the cellar log and the actual floor inventory. Those gaps are frustrating, and they put both quality and compliance at risk.

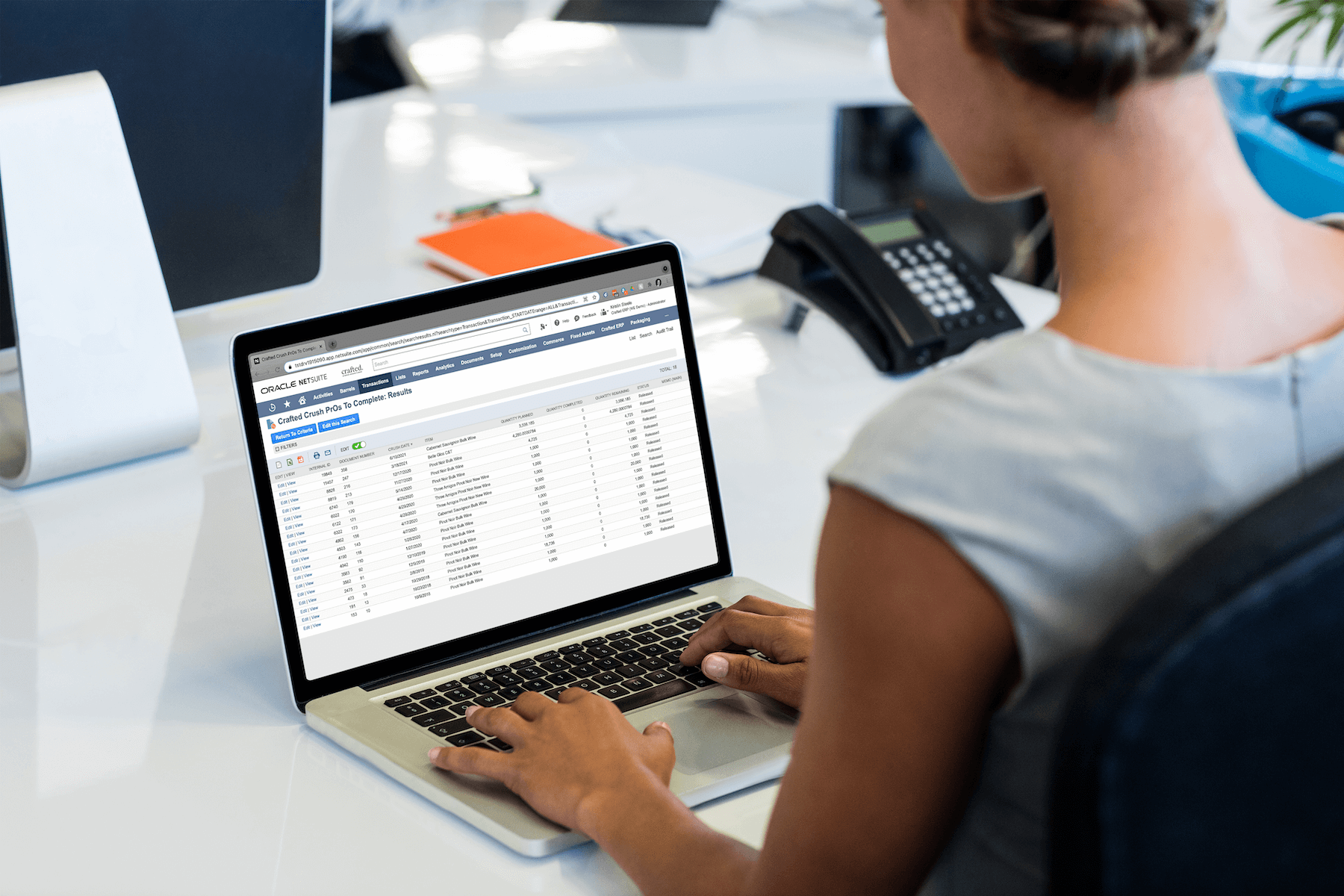

That’s where an ERP built for the beverage industry comes in. It doesn’t replace intuition, palate or craft. It safeguards them, ensuring every batch is consistent, traceable and ready for growth. While CEOs view ERP as a growth enabler and CFOs see it as a tool for financial control, production leaders understand ERP as a means to protect quality and consistency at scale.

The Pain Points on the Production Floor

If you’ve run a brewhouse, winery or distillery, you already know the challenges. These aren’t theoretical or abstract — they’re daily realities:

- Paper trail nightmare: You’re flipping through binders or chasing down sticky notes when you should be monitoring fermentation. A missing batch log can mean hours of detective work.

- Consistency challenges: You can nail a batch once, but replicating it perfectly, year after year, without precise records? That’s where things unravel.

- Inventory mystery: Nothing spikes blood pressure like a missing barrel or the wrong tank status on a whiteboard. When what’s on the floor doesn’t match what’s on the spreadsheet, you’re working blind.

- Audit anxiety: TTB or FDA audit on the calendar? Suddenly, your team is buried in prep work, combing through files, instead of doing their real jobs.

- Scaling concerns: The biggest fear — more volume means less control. No one wants their brand to grow only to hear that customers think “it just doesn’t taste the same anymore.”

CEO and Co-founder of HenHouse Brewing Collin McDonnell warned, “If you’re running everything through spreadsheets, there’s so much room for human error. Someone’s always going to get blamed, and then that person is going to have resentment…It’s weird to talk about an ERP as a way to get the team to get along better, but it’s super true.”

Production teams don’t fear hard work. They fear losing their edge as output scales.

Mastering Production from Grain to Glass

ERP replaces the chaos of clipboards and whiteboards with clarity, without sacrificing flexibility.

- From clipboard to tablet: Batch data is captured in real time, not transcribed hours later. You can walk the floor with a tablet instead of a binder, knowing the data is already logged, accurate and accessible.

- Historical batch analysis: Want to know what made that 2019 vintage shine? ERP lets you look back at every variable – lot numbers, fermentation temps, barrel treatments – and replicate success with precision.

- Lot traceability: Every bottle can be traced back to its raw materials. That’s peace of mind in an audit, but it’s also a competitive advantage when you need to prove quality to distributors or partners.

- Tank and barrel management: No more wondering “what’s in Tank 12?” One glance at your dashboard tells you what’s fermenting, what’s aging and what’s ready to move.

- Barrel aging cycles: Angel’s share is financial, not just poetic. ERP tracks revaluation and projected yield, so you’re not guessing how much will make it to the bottle.

Even shaving five minutes off a repeated process adds up. Multiply that by tens of thousands of cycles per year, and you’re talking about hundreds of hours given back to your production team. Hours that can be spent on innovation, quality control and artisanship.

Quality Control Integration and Compliance

On the production floor, quality and compliance are inseparable. If one falters, the other follows. ERP strengthens both in one stroke with:

- Automated data capture: Temperatures, gravities or lab results flow directly into the system. No more manual entry errors or missed checkpoints.

- Audit-ready documentation: Instead of scrambling for weeks, your reports are a click away. Audit prep shrinks from “drop everything for a month” to “run the report and keep working.”

- TTB/FDA compliance simplified: Complex, error-prone reporting becomes routine. No more double-checking numbers late at night.

- QC checkpoints built in: Every stage of production has QC guardrails. Deviations are flagged instantly so they can be corrected before they become problems.

Compliance stops being a tax on your time and becomes a natural extension of your quality program. It changes into something you’re proud to showcase, not something you dread.

Recipe Management and Innovation

For production leaders, recipes are the soul of your brand. ERP protects them, scales them and makes them smarter by:

- Protecting intellectual property: Recipes are securely locked down in the system with role-based permissions. Collaboration happens without exposing trade secrets.

- Scaling recipes accurately: Whether it’s 10 barrels or 100, ERP scales recipes without sacrificing flavor balance. Precision replaces guesswork.

- Cost analysis baked in: See the exact COGS of every recipe or variation. Know instantly whether that new hop blend or barrel finish is worth it financially.

- Version control: Every substitution or tweak is logged and approved. That way, no one is wondering months later, “Why does this taste different?”

Far from limiting creativity, ERP gives production heads the confidence to experiment and innovate. Neither has to come at the cost of consistency.

How Beverage Production Leaders Scale Craft Without Compromise

The heart of the production leader’s anxiety is that scaling will mean losing the artistry. ERP proves otherwise.

Myth vs. Reality

| Myth | Reality with ERP |

| Scaling means losing consistency. | ERP enforces QC standards at any volume. |

| New hires will never match veterans. | Guided workflows speed training and reduce errors. |

| Data will replace intuition. | ERP augments instinct, never overrides it. |

| Bigger means “selling out.” | ERP helps your culture scale along with your volume. |

Scaling doesn’t mean selling out. With the right system, your culture of craftsmanship is not diluted. While CEOs focus on markets and CFOs focus on investors, production heads keep the brand’s soul intact. ERP makes sure that, as the business grows, the craft only gets stronger.

Production Planning That Adapts

No production schedule is static. ERP is built for the unpredictable rhythm of beverage operations. Think of it as a cycle:

Harvest → Tank Scheduling → Multi-Product Coordination → Contract Production → Demand Shifts

Each stage flows into the next, supported by real-time visibility. When one variable changes — such as a late harvest, an unexpected contract order, or a surge in demand — the ERP automatically recalibrates capacity and schedules.

The result is agility without chaos. Production leaders gain confidence that even when the calendar shifts, quality and consistency won’t. It’s not about locking operations into rigid processes; it’s about giving you the flexibility to adapt with data you can trust.

Scale with Precision

You’re here to make a world-class beverage. Quality isn’t negotiable — it’s the promise poured into every glass.

At the end of the day, ERP doesn’t replace the brewer’s nose or the winemaker’s palate. It protects them. It captures the knowledge, workflows and details that make your product distinct, and makes them repeatable at scale.

Growth doesn’t have to mean compromise. Production leaders remain keepers of the craft with ERP. Only now, it’s backed by real-time data and built-in compliance.

Protect your promise of quality and keep your craft untouchable. Start with a Crafted ERP demo.