You didn’t start your distillery to babysit spreadsheets, but somewhere between your first label approval and your fiftieth batch, operations got complicated. Your inventory lives in five places. Costing is a guessing game. Compliance reports sneak up like hangovers. Any of this sound familiar?

If you’re scaling a craft distillery with paper logs and cobbled-together software, it’s not a matter of if those tools break down, it’s when. Distillery ERP does what your spreadsheets can’t. It streamlines operations, unifies departments, and gives every stakeholder — from the master distiller to the CFO — a single source of truth.

Let’s break down distillery ERP: who it’s for and why craft spirits producers are turning to industry-specific beverage management platforms.

Operational Pain Points: The Bottleneck Beneath the Barrel

Distilleries face a perfect storm of complexity: small teams, intricate production, aging inventory, heavy regulation and often rapid growth. Adding product diversification, such as canned cocktails or limited barrel finishes, multiplies the operational strain.

Most distilleries are battling some or all of the following challenges:

- Disconnected data: Ingredient sourcing lives in email, production is tracked on a clipboard, and sales numbers are buried in QuickBooks.

- Compliance chaos: Manual TTB reports are time-consuming and error-prone. One missing field can lead to steep fines or worse.

- Barrel blindness: You know barrels are aging, but where and how many? What’s their fill date? Char level? Losses?

- Unpredictable costs: With no real-time insight into the cost of goods sold, pricing strategies are more gut-check than data-backed.

- Operational drag: Teams spend more time tracking production than creating or getting products to the shelf.

The result? Slow growth, preventable waste, compliance risk and constant fire-fighting. Doesn’t sound like a scaling strategy to us. It sounds like survival mode.

The True Cost of Disconnected Systems

Can we be blunt? Spreadsheets are cheap, until they’re not. Disconnected systems cost your distillery in ways that include:

- Inventory errors: Miscounts in barrel or raw material inventory can result in tens of thousands of dollars in lost revenue or, worse, lost batches. Distillery ERP tracks inventory by lot, batch and location, reducing costly errors.

- Compliance risks: When your audit trail is a mix of PDFs, notebooks and crossed fingers, you’re vulnerable. A distillery ERP ensures automated, audit-ready records with full traceability from grain to glass.

- Missed financial clarity: Without integrated costing and real-time financials, profitability is hard to calculate. Distillery ERP systems provide CFOs with real-time visibility into COGS, margin per SKU, and forecasting data.

- Team burnout: Manual data entry drains morale. When every team member becomes a spreadsheet jockey, creative and strategic work takes a backseat. ERP systems reduce busywork and boost efficiency.

Diversification Is Fueling Digital Transformation

What worked for your flagship bourbon won’t work for your expanding product line. Distilleries are evolving from single-SKU producers to diversified portfolios, featuring ready-to-drink cocktails, barrel-aged liqueurs, seasonal releases and private-label partnerships.

More SKUs mean more complexity, including additional suppliers, various packaging formats and increased regulatory hurdles. A modern distillery ERP enables distilleries to manage growth without losing control, allowing for expansion without incurring excessive stress.

What Is Distillery ERP? (And Why It’s Different)

Distillery ERP is enterprise resource planning software tailored to the specific needs of beverage alcohol producers. Unlike generic manufacturing platforms, it doesn’t just accommodate barrel aging and excise tax reporting — it’s specifically designed for these purposes.

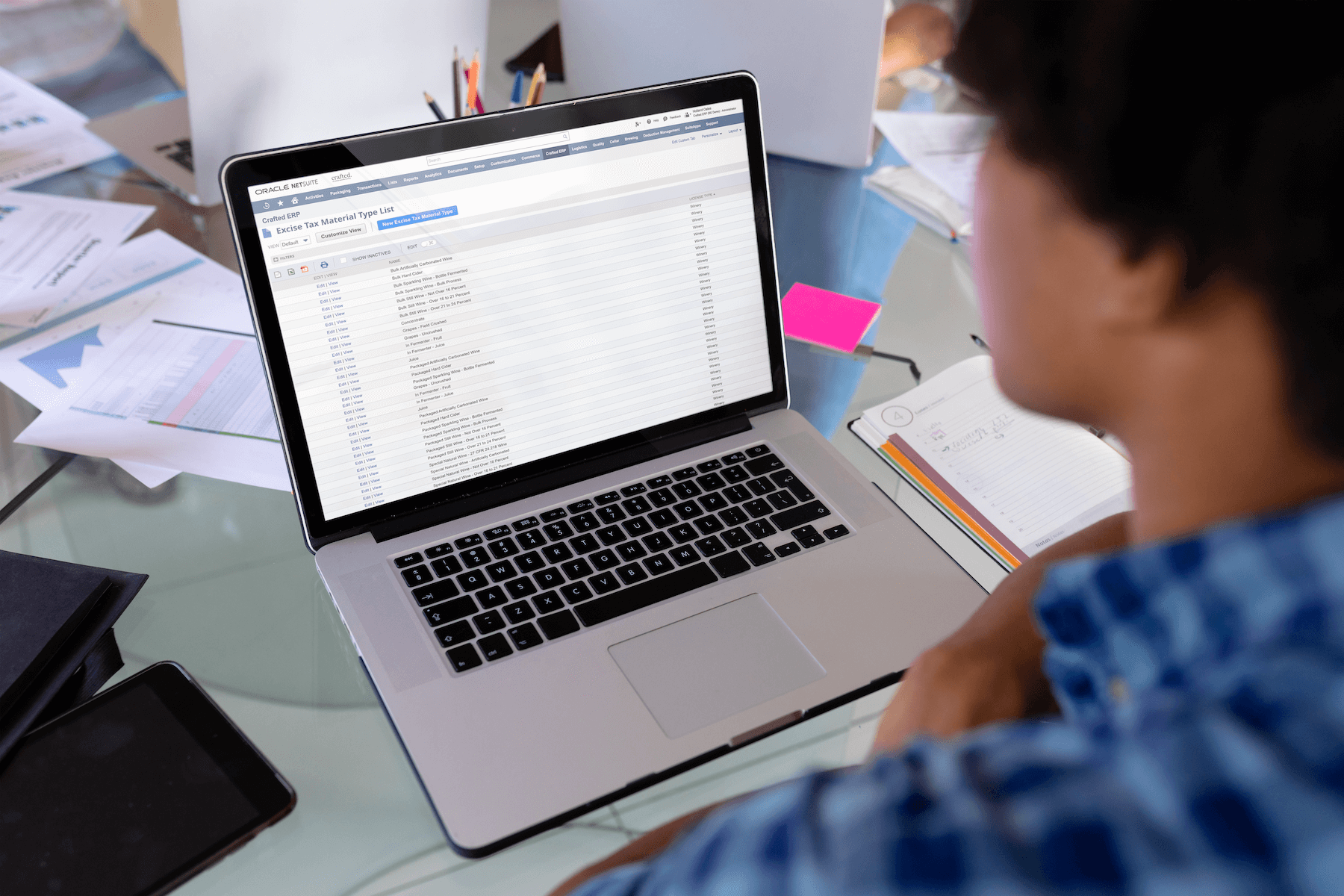

Crafted’s distillery ERP, for example, is a distillery-focused solution built in NetSuite and pre-configured for distilling operations. It manages:

- Batch and recipe control

- Barrel and maturation tracking

- Inventory and procurement

- Batch and lot traceability

- Financials and costing

- Regulatory compliance

- Demand planning and forecasting

It replaces patchwork systems with one unified platform. No more switching between inventory apps, finance tools and production logs. Just one integrated solution designed to work the way your distillery does.

Distillery ERP Benefits by Role

A distillery ERP pays dividends across every department. From the stillhouse to the back office, each team benefits from a shared source of truth that eliminates guesswork, reduces friction and fuels smarter decisions.

Some examples of how a purpose-built ERP supports the key players driving your distillery’s success include:

Master Distiller

- Recipe consistency: Lock in batch specs, track deviations and replicate successful runs with confidence.

- Barrel transparency: Access real-time barrel location, fill date, char level and aging status — no flashlight required.

CFO and Finance Team

- Accurate COGS: Know exactly what each SKU costs, factoring in aging, shrinkage and overhead.

- Real-time financials: Integrated GL, AR/AP and inventory ensure accurate reporting and cash flow visibility.

Operations Manager

- Production efficiency: Automate batch scheduling, track WIP and reduce downtime through capacity planning.

- Resource optimization: Sync procurement with demand to avoid over-ordering or stockouts.

Compliance Officer

- Automated reporting: Streamline TTB, FDA and local filings. Reduce errors and audit risk.

- End-to-end traceability: From raw ingredient to finished product, every lot is tracked and documented.

Supply Chain Lead

- Forecasting tools: Predict demand based on sales trends and lead times. Plan sourcing accordingly.

- Vendor coordination: Manage supplier contracts, performance and purchasing within the same system.

Choosing the Right Distillery ERP

Investing in infrastructure that will shape your business for years to come means more than just checking boxes. The ERP should accurately reflect how a distillery operates, scale with your ambitions, and be backed by people who speak the language of spirits.

Built for Distilleries

Generic ERP systems may handle standard manufacturing workflows, but distilling is anything but standard. From multi-year aging processes to stringent compliance regulations, spirits production introduces complexities that most platforms weren’t designed to manage.

In contrast, a distillery-specific ERP is pre-configured to run your business efficiently, out of the box. Systems like Crafted ERP come equipped with:

- Barrel lifecycle management: Including char level, fill date, warehouse mapping and aging status

- Angel’s share and shrinkage tracking: Automatically reflected in inventory and COGS

- TTB reporting workflows: Built directly into the production process

- Recipe management and batch control: Tailored for consistency and compliance

No retrofitting. No reengineering. Just software that speaks the language of spirits from day one.

Unified Platform

When your distillery runs on a patchwork of tools, even simple tasks become complicated. The gaps between those systems? That’s where errors, delays, and wasted time live.

A unified distillery ERP platform eliminates those gaps by connecting every department to a single source of truth. With one login, you can see what’s in production, what’s aging in barrels, what’s sitting in inventory, and how it’s all affecting your bottom line — in real time.

Here’s what that looks like in action:

- A production manager schedules a batch based on live inventory data.

- That batch automatically generates costs, which flow into your COGS.

- When the batch is bottled, it updates inventory and triggers tax reporting.

- Your finance team sees the entire lifecycle of every SKU, no emailing spreadsheets or syncing systems.

With integration this tight, decisions get faster, errors drop and your team can stop chasing data and start using it.

Scalability

Growth is incredible until your systems can’t keep up. Whatever the scenario, scaling without the right tech is like adding horsepower to a car with no brakes.

Distillery ERP should make expansion easier, not harder. That means:

- Multi-location management: Track inventory, barrels and production across sites without duplicating processes.

- Multi-entity financials: Run consolidated financial reports across brands, subsidiaries or geographic regions — no manual reconciliation required.

- Product line diversification: Whether you’re adding RTDs or non-alc SKUs, your ERP should flex to fit your model.

Whether you’re expanding from 5 SKUs to 50 or moving from 1 warehouse to 5, the distillery ERP scales up without requiring rework or reimplementation.

Industry Expertise

ERP software is only as strong as the people behind it. And too often, vendors sell platforms built for generic manufacturing, then try to “customize” them for distilleries after the contract is signed. It’s risky. You end up paying to educate your vendor on how your business works.

Crafted ERP flips the script. Built by a team of former distillers and bev-alc operators, the platform reflects a deep, lived-in understanding of the industry. That insider knowledge shows up in every module of the product, including:

- Barrel mapping that reflects real-world rickhouse layouts

- Angel’s share tracking that impacts inventory and cost

- TTB reports generated in the exact formats regulators expect

And just as importantly, that knowledge shapes how distillery ERP implementation, support and product development are handled. You’re working with people who’ve lived your challenges and built software to solve them.

More Barrels, More Problems? Not Anymore.

ERP cleans up your operations and clears the runway for distillery growth. It replaces friction with flow, silos with visibility and fire drills with foresight. It gives your team time back, puts data to work and brings control to the chaos.

Whether you’re managing 100 barrels or 10,000, launching canned cocktails or eyeing your next facility, the right ERP turns complexity into a competitive advantage.

Curious how Crafted ERP fits your role? We’ve bottled decades of distillery expertise into one platform — no chasers, no patchwork, no fluff. Let’s talk!

And if you’re wondering what makes the best distillery ERP solutions tick, don’t miss the next article in the series where we break down the distillery ERP features that separate the good from the best-in-class.