The beverage industry runs on razor-thin margins and relentless deadlines. Yet across production floors and back offices, teams are drowning in spreadsheets, duplicate data entry and manual reconciliations that consume 60 to 100+ hours every month. That’s not lean operations — that’s bleeding resources.

Here’s the reality check: while your production team meticulously tracks fermentation data in one system, your accounting team re-enters the same information into QuickBooks. Your compliance manager manually compiles TTB reports from scattered spreadsheets. Your warehouse staff updates inventory counts that never quite match what the books show. Each department works in its own silo, speaking different languages, creating a “Tower of Babel” that becomes more precarious with every new SKU.

The hidden cost isn’t just the actual hours worked by each employee — it’s what those hours represent. When your controller spends days reconciling disconnected systems instead of analyzing cash flow trends, that’s strategic capacity lost. When production managers burn afternoons generating reports instead of optimizing processes, that’s innovation stalled. When skilled employees become expensive data-entry clerks, that’s talent wasted.

The True Cost of Manual Operations

Let’s put numbers to the pain. A mid-sized beverage company with 50 employees typically has 5-7 people spending at least 40% of their time on manual administrative tasks. That’s roughly 2-3 full-time equivalents (FTEs) dedicated to moving data between systems, fixing errors and compiling reports. At an average loaded cost of $75,000 per FTE, you’re burning $150,000-$225,000 annually on work that adds no strategic value.

But the real damage runs deeper. Manual processes create cascading inefficiencies that are compounded throughout your business. Late financial closes delay pricing decisions. Inventory discrepancies trigger rush orders and expedited shipping costs. Compliance reporting errors risk penalties and audit complications. Each manual touchpoint introduces error potential — and in heavily regulated industries like beverage alcohol, errors carry consequences far beyond simple rework.

Consider the experience at Athletic Brewing Co. Before implementing Crafted, their teams struggled with the typical multi-system chaos. Different departments used varying tools, creating a reconciliation nightmare at month-end. After transitioning to a unified ERP platform, Controller Jillian Moccia reported cutting their close time by 10-15%. That’s not just a time savings — it’s the difference between making informed decisions on day 5 versus day 15 of the new month.

Automation Opportunities That Drive Real Returns

Modern beverage ERP doesn’t just digitize your existing processes — it fundamentally reimagines how work flows through your organization. Here’s where the transformation happens:

- Order-to-cash acceleration: Instead of manually creating invoices, updating receivables and reconciling payments across multiple systems, automated workflows handle the entire cycle. Orders flow directly from sales to production to fulfillment to accounting without re-keying. Payment processing integrates with your accounting automatically, and you collect customer payments faster.

- Production reporting revolution: Real-time data capture from the production floor eliminates the daily scramble of compiling tank reports, batch records and yield calculations. Dashboards update automatically, giving managers instant visibility into efficiency metrics, utilization rates and quality indicators. The reduction in report preparation time isn’t just about efficiency — it’s about getting actionable insights while they still matter.

- Financial close transformation: System-generated reconciliations, automated journal entries, and integrated subsidiary consolidation streamline the monthly close process, reducing it from a two-week marathon to a more efficient operation. When everything lives in one system, there’s nothing to reconcile between platforms. Intercompany transactions that once required manual elimination entries now process automatically.

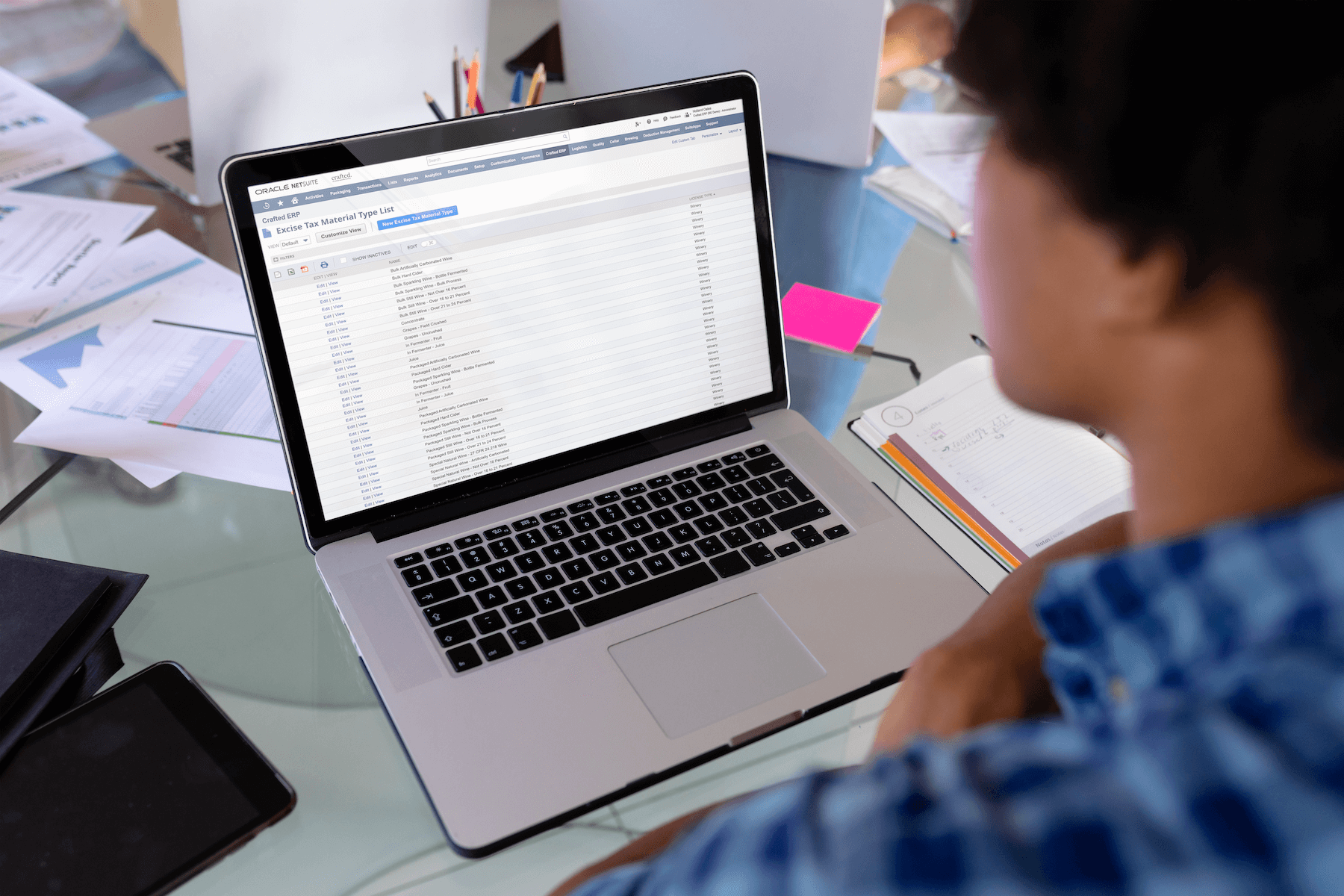

- Compliance without the chaos: TTB reports, excise tax filings and state compliance documents are generated in regulator-ready formats with a few clicks. No more transcribing production data into government templates or triple-checking calculations. The system maintains audit trails automatically, turning surprise inspections from panic-inducing to routine.

Building Labor Efficiency ROI That Lasts

The path to labor efficiency ROI requires more than just technology — it demands thoughtful implementation and change management. Start with baseline metrics: document current FTE hours spent on manual tasks, measure error rates, and track rework frequency. This isn’t about finding fault; it’s about quantifying opportunity.

Phase your rollout strategically. Begin with high-volume, repetitive processes where automation delivers immediate wins. Quick victories build momentum and demonstrate value, making broader adoption easier. When teams see colleagues reclaiming hours from mundane tasks, resistance transforms into demand.

Establish departmental champions who own their workflows and can troubleshoot issues before they escalate. These super-users become force multipliers, spreading best practices and maintaining standards after implementation is complete. Their success metrics — transactions per FTE increasing, manual entry hours decreasing, and error rates dropping — become proof points for expansion.

Document everything, but keep it simple. When processes live in the system rather than in someone’s head, scaling becomes possible. New employees onboard faster, and cross-training happens naturally. The tribal knowledge that typically leaves with key employees instead becomes embedded as an institutional capability.

Measuring Success: The Metrics That Matter

Labor efficiency ROI manifests in both hard and soft metrics. Track the obvious wins: reduction in overtime hours, decrease in temporary staff requirements, faster report generation. But don’t ignore the strategic indicators: employee satisfaction scores rising as work becomes less repetitive, decision-making velocity increasing as data becomes real-time, and customer satisfaction improving as order accuracy increases.

The most successful implementations see 50-70% reduction in manual data entry hours within the first year. Financial close cycles compress from weeks to days. Compliance reporting shifts from a monthly scramble to a routine process. These aren’t incremental improvements — they’re transformational changes that fundamentally alter how your beverage company operates.

The Competitive Edge of Efficiency

In the bev-alc industry, labor efficiency isn’t just about cost reduction — it’s competitive positioning. When your team spends less time on administrative tasks, they have more capacity for innovation, customer service and strategic planning. When your month-end close happens faster, you respond to market changes more quickly. When compliance becomes routine, you can confidently expand into new markets.

The beverage companies winning today aren’t necessarily the ones with the best recipes or the largest marketing budgets. They’re the ones who’ve turned operational efficiency into a competitive weapon. They’re closing their books while competitors are still collecting data. They’re launching new SKUs while others are reconciling spreadsheets. They’re scaling profitably while others are hiring more administrators.

Labor efficiency ROI isn’t just about the dollars saved, though those are substantial and measurable. It’s about transforming your organization from one that manages data to one that leverages it. It’s about freeing your best people from mundane tasks so they can drive growth. It’s building an operational foundation that scales with your ambitions rather than constraining them.

The question isn’t whether you can afford to modernize your operations. It’s whether you can afford not to. Every month you delay is another 60-100 hours burned on manual processes, another cycle of delayed decisions, another period where competitors with better systems pull further ahead. The ROI clock starts ticking the moment you begin implementation. In the bev-alc industry, where speed and efficiency determine survival, that timing matters more than ever.

Don’t leave your team trapped in spreadsheet purgatory. Connect with our beverage ERP experts to see how much time and money you could save with purpose-built automation. Schedule your ROI assessment today and discover why leading beverage brands trust Crafted to transform their operations from manual mayhem to automated excellence.