You’ve decided to take the plunge on distillery ERP. Smart move. But now what?

Implementation is where ambition meets real distillery growth. Where “this will transform our business” becomes “wait, we have to migrate how much data?” It’s the difference between buying a still and actually producing award-winning whiskey.

Here’s the truth: distillery ERP implementation isn’t a software project. It’s a complete digital transformation. And like aging spirits, rushing it ruins everything.

This is your roadmap from signing the contract to popping bottles in celebration. No fluff. No consultant-speak. Just the real steps that separate successful implementations from expensive disasters.

Before You Touch the Software: Pre-Implementation Prep

The real work starts before anyone logs in. Think of this as mashing before distilling — get it wrong here, and nothing downstream can fix it.

Clean Your Data (Or Pay Later)

Your data is probably messier than you think. That Excel file tracking barrels? It has three different date formats and “Rick’s special blend” listed 47 different ways.

The Data Cleanup Punch List:

- Standardize naming conventions: Is it “Bourbon Barrel #1234” or “BRB-1234” or “Barrel 1234 (Bourbon)”? Pick one. Enforce it.

- Verify inventory counts: When’s the last time someone actually counted every barrel? Every bottle? Every grain sack? Do it now while you can still fix discrepancies the old way.

- Document undocumented processes: That thing where Joe texts Sarah who emails Mike about barrel transfers? Write it down. All of it.

- Consolidate customer data: If “Ryan Bourbon Distributor” and “RB Distributors LLC” are the same company, merge those records now.

Assign Your Distillery ERP Implementation Team

This isn’t a side project. The people on this team need dedicated time, real authority, and thick skin. Because they’re about to challenge every “we’ve always done it this way” in your operation.

Essential Team Roles:

- Executive sponsor: Every distillery ERP implementation must have someone in leadership to champion change.

- Project manager: Your internal quarterback. Keeps timelines, manages resources, and, let’s be honest, herds cats.

- Production representative: Speaks for production and knows every quirk of your processes.

- Finance lead: Understands COGS, margins and why accurate costing matters.

- Warehouse champion: Lives and breathes inventory. Knows where everything is (or should be) located.

- Compliance officer: Understands and can speak to regulatory requirements in their sleep.

Lay the Foundation

You can’t build a rickhouse on mud. The first phase of implementation creates the solid ground everything else stands on.

System Configuration

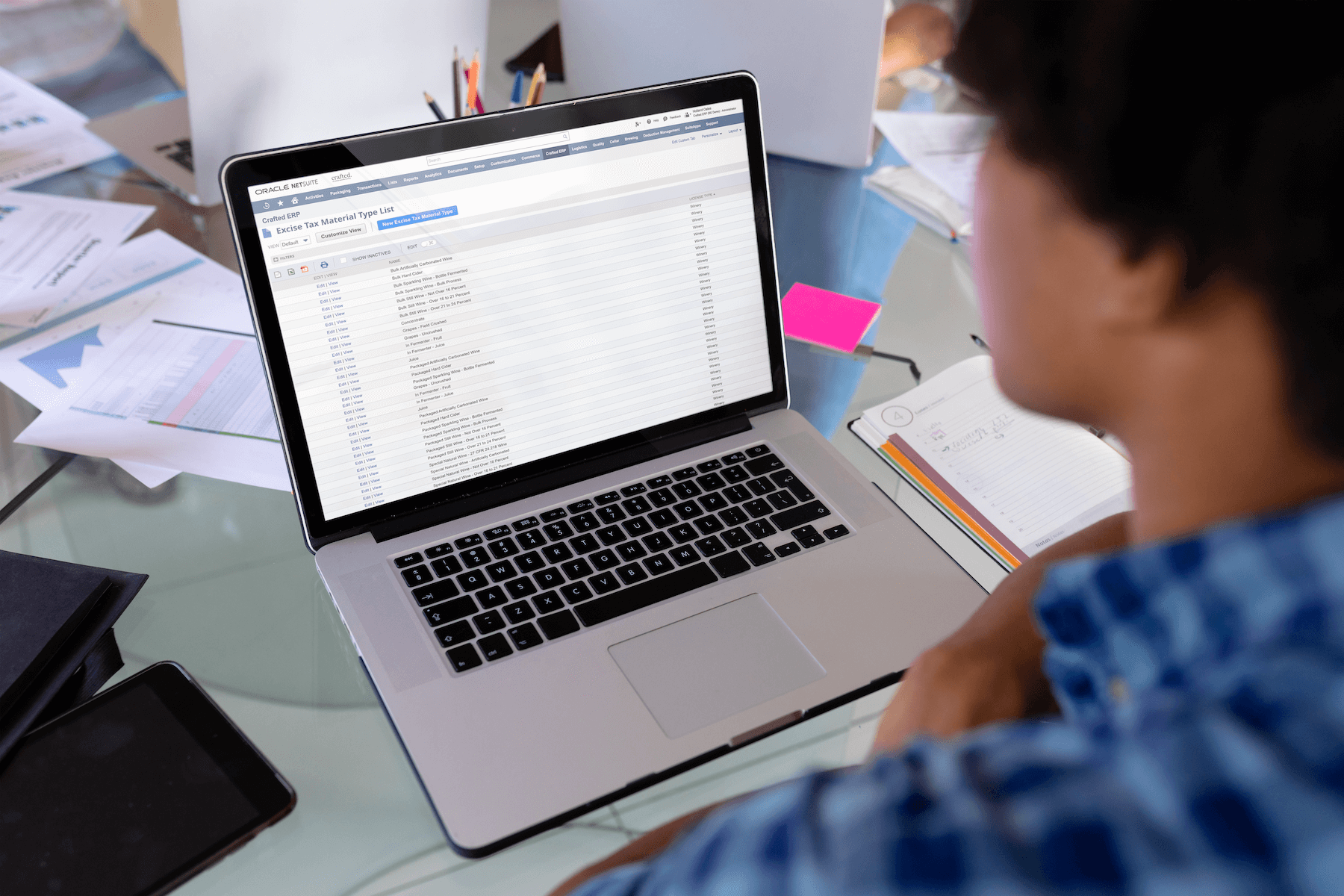

Your distillery ERP implementation partner should arrive with a distillery-specific template. Not blank software. Not a generic manufacturing setup. A real distillery configuration that knows what angel’s share means.

Week 1-2 Focus Areas:

- Chart of accounts aligned to distillery operations

- Basic master data: facilities, departments, users

- Tax rates and compliance frameworks

- Initial security roles and permissions

Process Mapping

Here’s where reality hits. Your implementation team will map your current processes, then show you which distillery ERP features best enhance those processes. Expect resistance. Expect “but we’ve always…” Expect breakthrough moments when someone realizes they’ve been doing unnecessary work for years.

Critical Processes to Map:

- Grain-to-glass production flow

- Barrel fill, aging and harvest workflows

- Inventory receiving and movements

- Compliance reporting sequences

- Financial close procedures

Create the Framework

This is where your distillery’s unique personality gets built into the system. Where “the way we do things” meets “the way successful distilleries do things.”

Core Configuration

Your ERP starts taking shape. Real products. Real recipes. Real warehouse locations. It should start looking like your distillery, not anyone else’s.

Top Priorities:

- Products & BOMs: Every SKU, every recipe, every packaging configuration

- Warehouse structure: Locations, bins and barrel storage areas mapped to match reality

- Production workflows: From milling to bottling, with all your specific steps

- Costing methods: How you’ll calculate true product costs, including aging

- Compliance templates: TTB reports configured for your unique needs

Data Migration Sprint

Remember that data cleanup? Time to move it. This isn’t copy-paste. It’s transformation. Your old data structure won’t match the new one, and that’s good. It means you’re upgrading more than software.

Migration Sequence:

- Static data first: Customers, vendors, items

- Open transactions: POs, SOs, work orders

- Inventory counts: Raw materials, WIP, finished goods

- Barrel inventory: Every barrel, its contents, age and location

- Historical data: What’s needed for reporting, not everything

Put it to the Test

Testing isn’t about checking if the software works. It’s about proving your business processes work in the new system. Every scenario. Every edge case. Every “what if.”

Scenario Testing

Run your business in the system. Not just happy-path transactions. The weird stuff. The exceptions. The things that happen at 4 p.m. on Friday before a holiday weekend.

Test Scenarios That Matter:

- Barrel breaks during transfer — how do you record the loss?

- Customer changes order after partial shipment

- Grain delivery arrives with moisture content out of spec

- TTB audit requests three-year-old production records

- Calculating COGS for a five-year-aged product released today

User Acceptance Testing

Your team takes the wheel. No consultants driving. No training wheels. Can they run the business? More importantly, can they run it better than before?

UAT Success Criteria:

- Complete a full production run from grain receipt to bottle

- Process month-end close in the system

- Generate accurate TTB reports

- Handle inventory cycle counts

- Manage customer orders and shipments

Let it Run Wide Open

Go-live isn’t a moment. It’s a carefully orchestrated transition. Like switching from pot stills to column stills mid-production — possible, but requires precision.

Cutover Planning

The weekend you go live, your business doesn’t stop. Orders still ship. Production still runs. But now it’s all in the new system. This requires military-level planning.

Cutover Essentials:

- Final data migration (the gap between test and live)

- Physical inventory counts synchronized to the minute

- Open transaction cleanup in legacy systems

- User access verification and testing

- Fallback procedures if something goes wrong

Hypercare Period

The first few weeks after go-live are crucial. You should have scheduled calls with your distillery ERP implementation partner to review how things are going and troubleshoot any issues.

Common Week 1 Issues:

- “How do I record this transaction?”

- “The report doesn’t show what I expected”

- “I can’t find the button for…”

- “This takes longer than our old way”

All normal. All fixable. All require immediate response.

How to Approach the First 90 Days

Going live with a modern distillery ERP system is like releasing a new product. The real work starts after launch. But remember, this isn’t a foot race. Pace yourself. Not every change has to happen on day 1.

- Month 1: Get comfortable with basic operations. Build muscle memory. Resist the urge to customize everything immediately.

- Month 2: Start tweaking. Those reports that are almost right? Fix them. Those workflows that feel clunky? Smooth them out.

- Month 3: Now you can start realizing the promise. Faster reporting. Better visibility. Actual data-driven decisions. This is where ROI becomes real.

From Roadmap to Reality

Distillery ERP implementation is a journey from chaos to control. From “I think we have inventory” to “I know exactly what we have, where it is, and what it costs.”

It’s not easy. If it were, everyone would have already done it. But for distilleries ready to scale professionally, it’s not optional. It’s the bridge between craft and enterprise. Between potential and performance.

Your roadmap is clear. Your team is ready. Your data is (getting) clean.

Time to stop managing spreadsheets and start managing growth.

Ready to get started? The team at Crafted ERP has guided dozens of distilleries through this exact journey. No surprises. No detours. Just a clear path from where you are to where you need to be.