Distillery growth is thrilling…until your operations start buckling under the weight of success. What used to work suddenly slows you down. Reporting takes hours. Compliance becomes a gamble. Teams are stretched thin. And every slight inefficiency begins to erode the cash flow.

This is the point where grit and hustle are no longer enough, where old tools create new problems. That moment? It can be subtle, but certainly unmistakable.

You’re standing at the distillery growth threshold: the tipping point where distillers stop duct-taping their tech stack and start investing in infrastructure built to scale.

What Got You Here Won’t Get You There

Every successful distillery hits a point where the old playbook starts to crack:

- Manual processes buckle under complexity. That Google Sheet that tracked barrels just fine two years ago? Now it’s 40 tabs deep and three people behind.

- Cash flow becomes critical. Aging inventory ties up capital. Margin pressure intensifies. Delayed visibility into financials is inconvenient and, worse, risky.

- Predictability trumps hustle. Distillery growth requires forecasting, planning and precision, not another spreadsheet and another late night.

At some point, working harder stops working. And that’s when distilleries hit the growth threshold.

But how do you know when to hold off and when to go all-in?

The Cost of Waiting Too Long

Let’s talk real numbers. If you’re managing production with a patchwork of Excel files, email chains and whiteboard calendars, it’s costing you:

- Product complexity overload: Each SKU has 5–15 components. Managing that manually increases the likelihood of mistakes, such as inventory mismatches, incorrect blends and mislabeled products.

- Hidden costs pile up: Errors mean rework. Rework kills margin. Missed reorder points lead to production delays. Noncompliance can trigger audits or fines. Add it up.

- You fall behind the curve: Competitors that invest in modern infrastructure operate leaner, move faster, and make decisions based on data. If you can’t keep up, you’re at a serious strategic disadvantage.

Waiting is expensive. The longer you delay the upgrade, the more margin and momentum you lose.

The Risk of Moving Too Early

ERP isn’t a magic wand in all scenarios. Deploying a flagship system while you’re still in early stages can backfire.

Move too early and you risk:

- Overkill systems: If you’re not managing complex production, multiple locations or a broad SKU mix, a full ERP may be more than you need, for now.

- Poor change management: Without the right rollout plan, ERP can overwhelm teams. Distillery ERP implementation doesn’t work without adoption.

- Misaligned ROI: If your distillery isn’t big enough to absorb the time and cost of onboarding ERP, the payback period might stretch longer than it should.

So, how do you know if it’s the right time? The move to ERP should be strategic, not reactionary. That’s why recognizing the signs matters.

7 Signs Your Distillery Is Ready for ERP

Straight from the floors of real distilleries that made the switch to ERP. These signs aren’t hypothetical. They’re real signals from distilleries on the verge of scalable transformation.

1. The 2-Hour Rule

If your team spends more than 2 hours a day cobbling together reports from different systems (or, worse, spreadsheets), you’ve outgrown your tools.

2. Inventory Incidents

You can’t say with certainty what’s available to promise right now. Inventory is “mostly right,” until you oversell or short a customer.

3. Compliance Close Calls

If your compliance reporting feels like a scramble, and you’ve had at least one “we might miss that TTB deadline” moment, you’re flirting with risk.

4. Production Puzzles

You don’t know your true cost per SKU, per batch or brand. You’re making pricing decisions based on instincts, not data.

5. The 3% Revenue Rule

If inefficiencies, think labor waste, costly errors or missed revenue, are eating 3% or more of your annual revenue, you’re bleeding margin. (Spoiler: Most distilleries are.)

6. Distillery Growth Constraints

You hesitate to launch new products, take on custom contracts, or expand to new facilities. Not because the market isn’t there, but because your systems can’t support it.

7. Strategic Catalysts

You’re preparing for a capital raise, acquisition or partnership. Investors want numbers, not napkin math. A modern distillery ERP makes your operation transparent, scalable and fundable.

Growth Requires Systems, Not Just Hard Work

Let’s say you’ve nodded “yes” to a few of those signs. Now what?

It means change is afoot at your distillery. And with change comes the need for infrastructure that grows with you. Not a patch. Not a plug-in. A purpose-built platform.

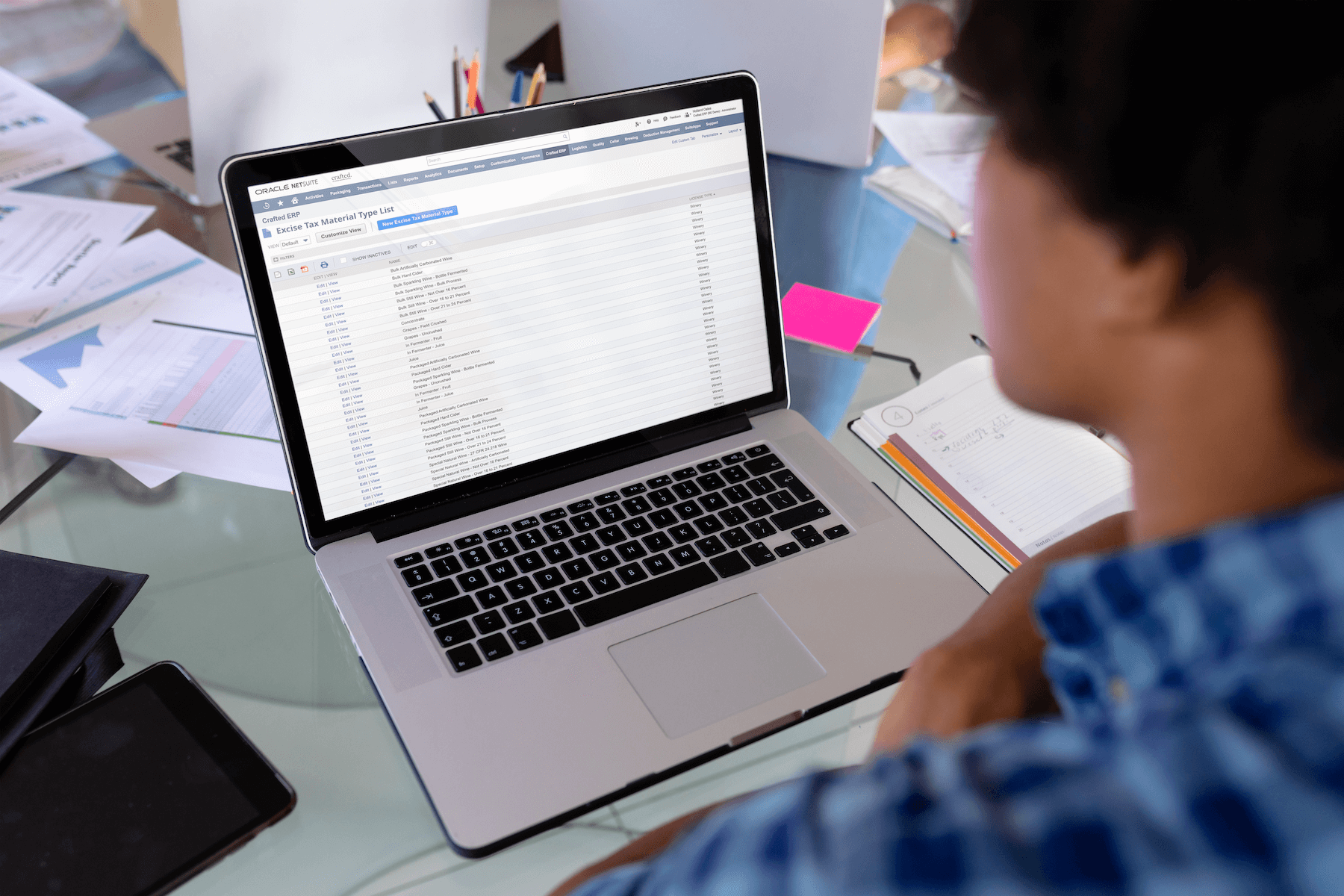

Crafted ERP is built for this moment. Built in Oracle NetSuite and designed for distilleries, Crafted consolidates your production, inventory, finance and compliance workflows into one clean, scalable system.

No more juggling disconnected tools. No more sleepless nights before audits. Just distillery ERP features like:

- Real-time barrel and batch tracking

- Live inventory and demand planning

- Lot-level traceability for compliance

- COGS and financials you can trust

- Support from people who’ve worked in distilleries, not just sold software to them

Ready to Cross the Distillery Growth Threshold?

Most distillery leaders don’t wake up one morning and say, “Let’s buy an ERP.” What happens instead? Reality creeps in.

Reporting takes longer. Errors get costlier. Your team hits its limit. And you start asking, “What’s going to break next?”

That’s the moment. That’s the threshold. And when you hit it, the question isn’t whether to invest in ERP. It’s how long you can afford not to.

Ready to start a conversation to review your current pain points and find out just how close you are to needing ERP?