Was accidental IT manager on your list of what you wanted to be when you grew up? You didn’t hire a head distiller to spend their week buried in spreadsheets. And you didn’t invest in barrel-aged brilliance only to lose sleep over inventory black holes, last-minute compliance scrambles, or costing data you can’t trust.

But here you are scaling faster than your systems can handle. This is where these key distillery ERP features change the game and your future.

This isn’t your dad’s ERP. Designed explicitly for distilleries, it gets how barrel aging affects cash flow. It knows angel’s share is more than just poetic loss. It’s your central nervous system, built to unify production, finance, inventory, compliance and more in one clean, connected platform.

To appreciate what a modern ERP brings to the table, it is helpful to understand what it replaces.

What Distillery ERP Replaces

Before ERP, most distilleries are held together by duct tape and Excel. It works until it doesn’t. Here’s a peek inside the average pre-ERP tech stack:

- Spreadsheets for production planning, barrel tracking and packaging runs

- QuickBooks or Xero for financials, disconnected from real-time inventory or COGS

- Manual logs or scattered digital files for TTB reporting

- Whiteboards, sticky notes and Slack for production scheduling

- File folders (yes, the literal kind) for licenses and label approvals

- Basic inventory apps that track ingredients but can’t account for aging, loss or revaluations

The result? You already know this: siloed data, inconsistent reporting, poor forecasting and zero visibility across departments.

Distillery ERP replaces all of this. No more hopping between tools. No more “I’ll check and get back to you.” Just clean data, real-time access and confident decisions.

Core Distillery ERP Features That Separate Purpose-Built ERP from the Pack

Now that you have a little background, you need to know the four distillery ERP features your system absolutely must have.

1. Production Management

Why It Matters: This is your heartbeat. From grain to glass, your production planning needs precision, visibility and flexibility.

Full-scale production management tailored to distilling should have:

- Real-time batch tracking: Capture data at every stage: milling, mashing, fermenting, distilling, bottling — with automated lot traceability and digitized batch logs. This ensures compliance and repeatable quality.

- WIP routing: Route work-in-progress through each stage of production, from raw materials to finished goods, with defined workflows and real-time updates.

- Drag-and-drop scheduling: Visual planning boards enable you to move production orders with intuitive tools, allowing you to quickly adapt to changes in capacity, inventory or labor.

2. Barrel Management

Why It Matters: Your barrels are assets. You need to know where they are, what’s inside them, and how they’re aging — without relying on a flashlight or a spreadsheet.

Advanced barrel management should be designed to do:

- Barrel mapping & warehouse visualization: View the physical location, age, liquid type and cooperage characteristics of every barrel with interactive maps.

- Angel’s share calculations: Automatically capture losses from evaporation during harvest, with calculations built into COGS and inventory value.

- Maturation tracking & revaluation: Revalue barrels periodically based on age, labor, storage costs or location. Keep financial data aligned with physical aging.

3. Financial Integration That Matters

Why It Matters: Distilling is capital-intensive. You need to know your true margins at the batch, SKU and brand level. It’s time to move beyond end-of-month accounting to real-time financial insights.

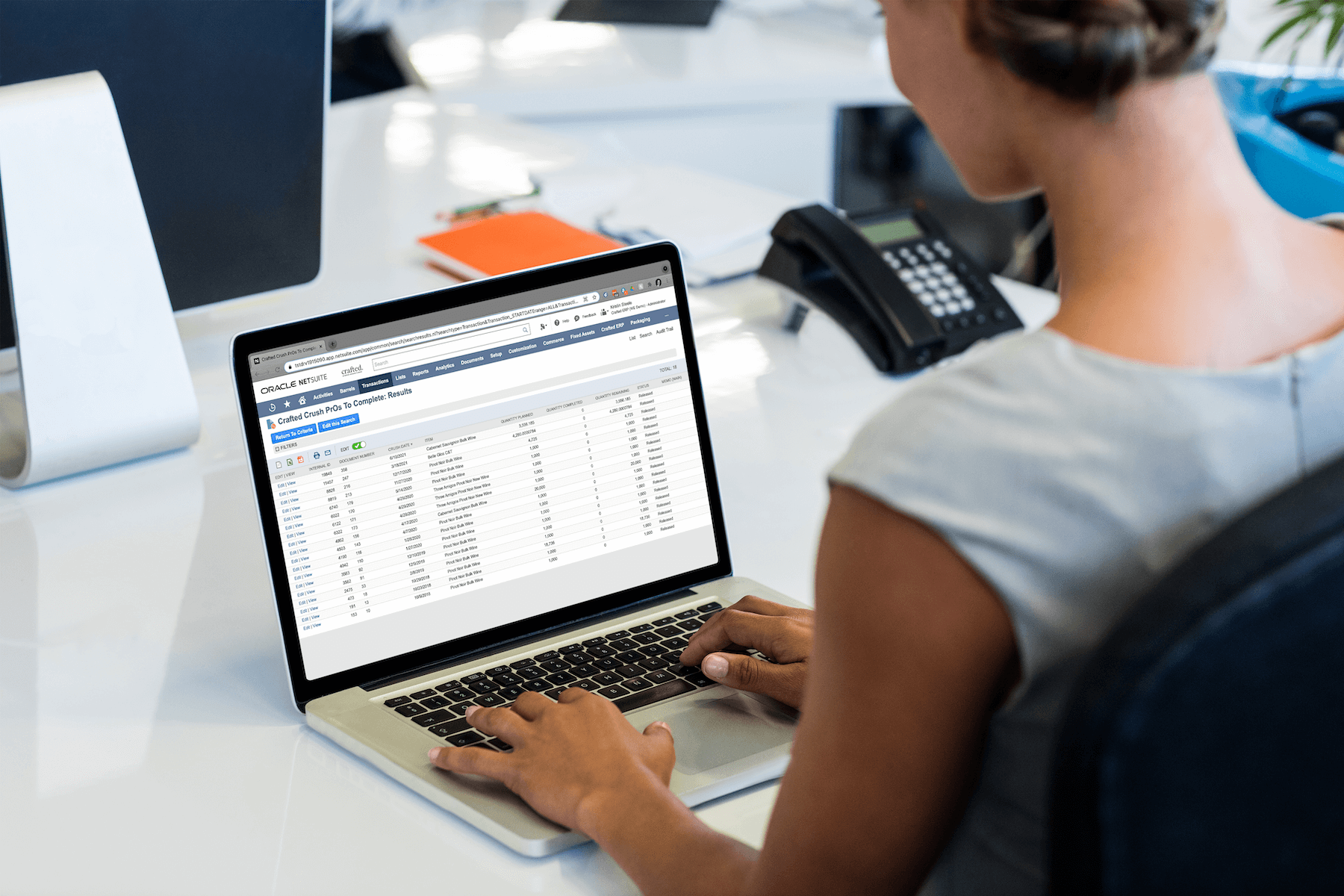

A platform built in Oracle NetSuite means finance isn’t bolted on; it’s baked in with:

- Automatic cost allocation: Labor, materials, storage, shrinkage — all costs are tracked and assigned down to the barrel and bottle. No manual spreadsheets.

- Real-time profitability analysis: Instantly know your margins per product, batch or customer. No more waiting for reports.

- Multi-entity support: Whether you’re running multiple facilities, brands or geographic locations, your platform should consolidate financials without confusion.

4. Compliance & Quality Control

Why It Matters: Compliance isn’t optional. TTB audits, label registrations, license tracking — it all has to be airtight. One misstep can cost you time, reputation and revenue.

The platform should remove the drama from distillery compliance with:

- Automated TTB reporting: Generate reports in the required formats, with the data already connected to production and inventory activity.

- Lot traceability: Track every input and output for instant recall readiness, down to the barrel, bottle or batch.

- Label & license management: Store artwork, approval dates and renewal schedules in one place. Never miss a refile or registration again.

Crafted ERP Distillery Software: Built to Do More Than Keep Up

Most ERP vendors don’t understand what it takes to run a spirits operation. Crafted is different. It’s built by distillers, for distillers, and it shows.

What sets it apart:

- Built in NetSuite: Enterprise-grade reliability and scalability, with full cloud access from any device.

- Configured for distilling: Features like angel’s share accounting, barrel mapping and excise tax workflows are native.

- Designed to scale: Whether you’re adding SKUs, expanding to new locations, or launching RTDs, Crafted grows with you.

- Supported by industry experts: From distillery ERP implementation to support, you’re getting a team of former distillers, brewers and winemakers and a partner who gets your business — and where it’s going.

From Distillery ERP Features to Futures

Distillery ERP features are only impressive if they make your life easier. And when they’re built for distilling, not duct-taped from generic manufacturing tools, they do just that.

Stop roughing it. Start running it.

You didn’t sign up to spend weekends sorting spreadsheets, hunting for inventory or staring down a TTB notice. That’s dysfunction, not distilling. Crafted turns those pain points into clarity, control and capacity.

Think your distillery is teetering on the edge? Hang tight for the next installment in this series, where we’ll explore the seven unmistakable signs that you’ve hit your distillery growth threshold.

Missed Part 1 of our series? Read all about how modern distillery ERP transforms spirits operations from spreadsheet chaos to unified control.