Craft beer is at a crossroads. Distribution has become more competitive, making it harder for small brands to gain valuable shelf space. Younger generations are seeking low- to no-alcohol beverages for a healthier alternative. Not to mention supply and labor costs continue to rise, and inflation has caused buyers to tighten their spending.

While the total number of breweries in the U.S. is up a small amount from a year ago (from 9,242 in June 2022 to 9,456 in June 2023) the craft beer market is maturing and there is a dire need for innovation, product diversification, brand expansion and new customer acquisition.

As the Brewers Association Chief Economist Bart Watson recently stated in his midyear update, craft beer isn’t going anywhere, but the shifts in the market are calling for change. “Collectively, craft still needs new ideas and new strategies to move beyond our current normal, which is a slow-growth environment. There is plenty of opportunity for growth within new channels, occasions and customers.”

One such strategy for craft brewers to forge ahead and cement their stake in the market is to consider a venture into distilling. With similar supply needs, processes and equipment, it can be an easy transition for craft beer makers to transform into a brewstillery. Craft spirit sales have overtaken beer sales for the first time ever, which would allow craft brewstilleries to attract a new type of customer. While the path from brewing to distilling may be halfway paved, there are several considerations craft brewers must examine beforehand.

The Commonalities Between Brewing and Distilling

Stepping into the world of alcoholic beverages, one quickly realizes the intricacies of each beverage production process. From the art of brewing to the craftsmanship behind a bottle of whiskey, each drink tells a unique story. Yet, when we delve deeper into the science and art of brewing and distilling, there emerges a fascinating tapestry of similarities and shared origins.

Drawing a parallel between brewing and distilling uncovers similar foundations, revealing a story that goes back centuries. The ancient practices of fermenting grains, fruits and other raw materials to produce intoxicating drinks have evolved and specialized over time. But beneath the surface, the basic principles remain intertwined.

This synergy suggests that for brewers, the journey to distillation isn’t about charting unfamiliar waters but rather exploring another branch of a tree they’ve already climbed. It’s a deepening of expertise, a dive into a related discipline. This signifies that the shift from brewing beer to creating spirits is diversification, not an entirely new venture. By understanding and embracing these common roots, breweries can unlock new potentials, extend their market reach and appeal to an even broader audience.

Familiar Foundations

The fermentation process; similarities between brewing beer and creating spirits:

Brewing beer and creating spirits share a fundamental stage: fermentation. Yeast consumes the sugars in the base mixture during this step, leading to the production of CO2 and alcohol. This overlap simplifies the transition from brewing to distilling and provides a firm groundwork for this new venture.

The use of raw materials such as barley, rye and corn:

Brewers and distillers often tap into similar raw material sources. Both sectors work with grains such as barley, rye and corn. The behavior of these materials during the fermentation process is a valuable shared knowledge point brewers can bring into the distillation realm.

The Diverging Paths

There is an undeniable common ground between brewing and distilling. However, each takes its unique route after the fermentation process. To convert from brewing to distilling, beverage producers must keep a few key differences in mind.

The distinction between the distillation and brewing processes:

Brewers halt at fermentation, and distilling requires an additional distillation process. This increases the alcoholic strength and alters the character of the finished beverage. Distillers often subject their product to aging, a process mostly unused at breweries.

Additional equipment and workforce requirements:

Breweries and distilleries share a fermentation tank in their setups. The latter necessitates additional equipment, including a still. A shift to distilling involves learning to navigate this equipment. Existing brewery staff, accustomed to the brewing process, could be well-suited for distilling with additional training in operating the new machinery.

The Practical Considerations of Brewery Expansion

Entering the distilling market holds immense potential for diversification and growth. Yet, it certainly includes complexities and hurdles. The path to successful brewery expansion involves managing regulatory constraints and making significant operational adjustments.

Regulatory Complexities

Local, state and federal licensing requirements:

Brewing and distilling regulations are prevalent at local, state and federal levels. All these entities impose licensing stipulations. Efficient navigation through this thicket of requirements is crucial before opening a distillery offshoot. The U.S. Alcohol and Tobacco Tax and Trade Bureau (TTB) handles federal matters. Regulatory bodies exist within each state, and statutes can vary significantly from state to state.

Operational rules and different state mandates:

These regulations encompass operational concerns. In some states, a single business location might not operate both a brewery and a distillery. On-site sales and distribution needs fluctuate. Knowing how to handle these mandates presents a challenge for breweries looking to expand into distilling.

Operational Adjustments

Investing in educational initiatives for brewers on distilling nuances:

The fundamental principles of fermentation are shared territory between the two approaches, but distilling involves nuances that brewers might not be familiar with. Starting a distillery requires brewhouse staff to grasp new skills. This requires ample investment in education and training. Steps such as the methods of separating alcohol and capturing the desired spirit cuts require detailed expertise. This highlights the necessity for learning programs.

Proper dilution, still safety, and other technical expertise:

Safety measures around still operation, the safe limits of alcohol concentration and proper dilution practices are skills not often found in brewing processes but critical in distilling. A solid investment in mastering these areas ensures smooth operations when all systems are set to go.

Planning for a Successful Distillery Expansion

Transitioning from brewing to distilling requires more than just acquiring a still and other necessary equipment. Consider these key factors for smooth expansion.

Space and Equipment Demands

Importance of separate facilities for brewing and distilling:

Distilling beer isn’t just brewing it twice. Legal and operational complexities often demand breweries to often operate distilleries in a separate location. Cross-contamination prevention is another reason for separating facilities. Expansion into distilling often involves significant real estate considerations.

Warehouse space for barrel aging and storage considerations:

Aging spirits in barrels is a common practice in distilling. Demand for warehouse space often balloons when breweries expand their operations to include a distillery. Storage considerations emerge if bottling happens on site. Expansion planning needs to take into account the increased space requirements.

The Significance of Starting Big

The risk of underestimating initial equipment needs:

Breweries embarking on distilling often find themselves trapped in a common predicament: underestimating initial equipment needs. When faced with scaling their operations, they realize the limited capacity of their existing equipment. It pays off to invest in bigger tanks and robust infrastructure from the start.

Learning from the experiences of others; the trend of breweries wishing they started with larger stills:

Echoed by many in the industry, starting with larger stills rather than smaller operational ones is key to efficient expansion. Stories from other brewstilleries uncover a consistent trend: they wish they had started bigger. Embracing this wisdom can prevent capacity bottlenecks down the line, leading to smoother operations and production scale growth.

Tapping into the Growth of Ready-to-Drink Offerings

A distillery addition to a brewery extends beyond product range enhancement. The action strategically capitalizes on a landscape shift that favors ready-to-drink (RTD) offerings.

The Rise of the RTD Market

RTDs include craft cocktails in a can, malt-based products (FMBs) and spirit-based seltzers gaining rapid popularity. Recent years have seen these offerings dominate the beverage market. According to the Distilled Spirits Council in 2022, RTDs experienced a revenue increase of 42%. This indicates a high customer demand for these convenient products that a brewstillery or distillery could both satisfy.

Importance for brewers considering diversification into distilling:

Impressive growth figures matter for brewers eyeing the distillery space. A distillery can act as a gateway to the RTD sector, offering a new way to reach consumers and diversify revenue streams. For many, entering the distilling space is not about making spirits alone, it also involves stepping into lucrative RTD products.

Connecting with a Younger Audience

IPAs and stouts won’t be fading away anytime soon. However, craft breweries are facing challenges in attracting a younger audience who are eagerly exploring other beverage categories. Reports show that Gen Z, for instance, have a preference for spirits and wine over traditional beers.

Adding a distillery opens access to younger patrons less fervent about traditional beers. Spirits and RTDs offer a wide gamut of novel flavors and variations. These can be a major pull for younger consumers. Distillation opens doors to a demographic unsaturated by craft beer alone.

Is it time to forge ahead?

Adding a distillery to your existing brewery operation is a decision that invites careful consideration, execution and planning. The potential benefits make it an endeavor worth exploring.

Foundational overlaps exist between the brewing and distilling processes that make the transition naturally favorable – shared fermentation basics and common raw ingredients, to highlight a few.

Additional complexities, including regulatory frameworks and additional technical expertise, call for preparation and training. Investing in sizable facilities and equipment at the onset can save expansion bottlenecks later on.

Diversifying product offering is one benefit of launching into distilling. It also opens doors to the thriving RTD product arena, providing an engaging avenue to attract younger consumers. Given this potential for product diversification and market expansion, a brewer’s venture into distilling promises exciting possibilities and new growth horizons.

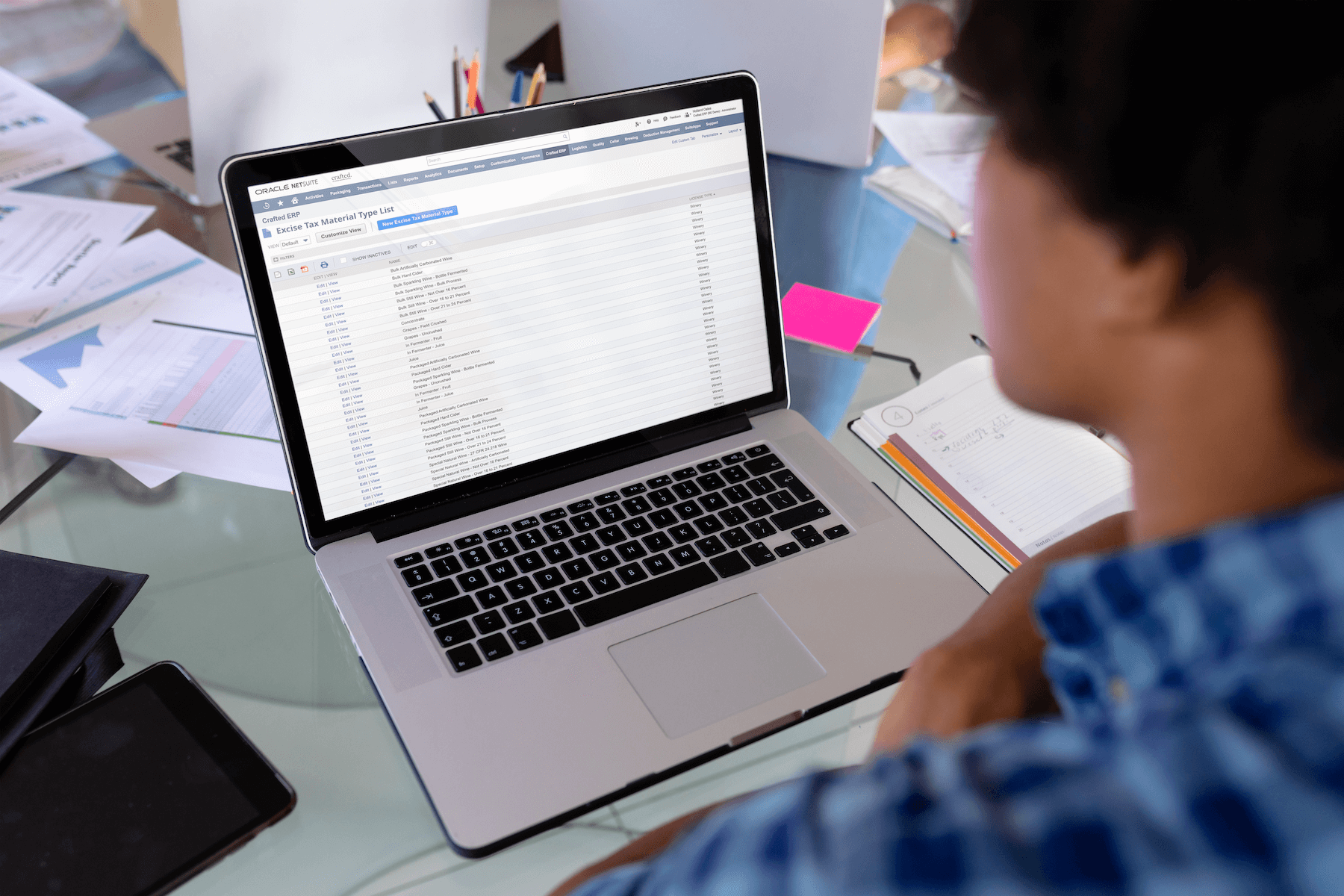

Interested in starting – or growing – a brewstillery? Crafted ERP has the solution for you. With a software platform built specifically to unite the brewing and distilling processes, we can offer a complete solution that meets all your business needs. Ready to give it a try? Reach out to us to set up a call.