California’s wine industry is at a critical juncture. While sales of white wine are increasing, the consumption of red wine is falling, leaving many growers with more grapes than they can sell. Experts estimate that 50,000 acres of vines should be pulled to bring supply back in balance — a drastic but necessary move.

Before you think this is just a California problem, think again. Vine removals are happening globally, with Chile, France and Australia cutting back to manage oversupply. Meanwhile, bulk wine markets are flooded, grape prices are plummeting, and some fruit isn’t even making it off the vine.

For growers and producers, the question is how to turn surplus into opportunity. Traditional solutions, such as bulk wine sales and vine removals, are in play. Still, some wineries are taking a more creative approach by repurposing surplus grapes for everything from functional beverages to spa treatments.

So, what does the future hold for California’s excess grapes and wine, and how can the industry move forward in a way that makes sense both in business and sustainability? Let’s take a look.

The Scope of California’s Grape Oversupply: How Much Surplus Are We Talking About?

California’s 2024 grape crush totaled 2.844 million tons, a significant drop from 3.685 million tons in 2023, making it the smallest crop since 2004. Despite the lower yields, 100,000 tons of grapes were left on the vines, signaling that demand isn’t keeping up with supply. At the 2025 Unified Wine & Grape Symposium, experts recommended that over 50,000 acres of vines be removed to help steady the supply.

With surplus comes a shift in prices. Napa growers who once sold fruit for $15,000–$20,000 per ton now see it go unsold. Some growers are selling Chardonnay for as little as $500 per ton, which barely covers picking costs.

What’s Driving the Surplus?

A combination of market shifts, economic pressures and climate events have led to the current oversupply:

- Declining wine consumption: U.S. wine sales have dropped since 2021, with a 6% decline in 2024.

- Generational shifts: Gen Z and Millennials aren’t drinking wine at the same rate as older generations, leading to long-term demand concerns.

- Inventory backlog: Wineries still have excess wine from previous vintages sitting in tanks and barrels, reducing the need for new fruit.

- Bulk wine price collapse: Prices have dropped, making it difficult for growers to break even.

How Is This Impacting Growers, Winemakers and the Broader Industry?

The financial strain for growers is mounting. Vineyard managers see contracts canceled or reduced, leaving them with unsold fruit and tough decisions about pulling vines or absorbing losses. Some growers are blending cheaper Sonoma grapes into Napa Cabernet to cut costs — taking advantage of the 15% rule that allows non-Napa fruit in Napa-designated wines without disclosure.

On the winery side, premium brands are faring better. However, producers focused on value-driven wines (under $12 per bottle) struggle to compete with an oversaturated market.

Economic & Environmental Considerations

- Cost of maintaining vs. removing vines: Vine removal is expensive, and with low grape prices, many growers are stuck in a cycle of diminishing returns.

- Sustainability concerns: Wasted grapes mean wasted resources — water, labor and emissions from production — raising questions about how the industry can reduce waste while staying profitable.

Traditional Solutions: How the Industry Has Managed Surplus Historically

There are a few tried-and-true ways to deal with grapes excess. Some come with steep trade-offs, while others depend on market conditions that are constantly shifting. Here’s how growers have historically managed surplus fruit — and why some of these solutions aren’t as reliable as they used to be.

Pulling Vines: The Cost of Cutting Back

When demand drops and there’s too much fruit in the pipeline, many growers rip out underperforming vines to cut costs and rebalance supply. In California, tens of thousands of acres have already been removed, and more are expected to follow.

Beginning in 2025, vineyard removal will face even greater financial and logistical challenges. Under new regulations related to SB-705, which was signed in 2003, vine removals in the San Joaquin Valley Air Pollution Control District can no longer be burned. Instead, growers must rely on alternative and significantly more costly disposal methods. Estimates indicate that removal costs will increase to $2,000–$3,000 per acre, up from the previous $1,500–$1,600 per acre.

This significant financial hurdle could drive some small and mid-sized vineyard owners out of business. Growers who may have once proactively removed underperforming or diseased vines might now hold off on removals, leading to further supply imbalances. Others must decide whether removal costs outweigh the long-term savings of reducing vineyard acreage in a saturated market.

While full burn bans are taking effect in the San Joaquin Valley, Napa County has taken a different approach. The Napa Valley Grapegrowers’ (NVG) Vineyard Burning Task Force has developed a six-step Low-Smoke Agricultural Burning Program designed to significantly reduce the smoke produced during vineyard burns. NVG claims to achieve a virtually smoke-free burn, offering a potential middle ground between eliminating burns altogether and maintaining affordable vine disposal practices.

The question is whether other regions will advocate for similar phased-out approaches or if full burn bans will become the norm statewide. Either way, for growers already struggling with falling grape prices and shifting demand, the cost of pulling vines is yet another pressure point in an already challenging market.

Bulk Wine Markets: A Saturated Option

Selling surplus grapes as bulk wine or juice has been a safety net for growers and wineries for decades. It allows producers to offload extra fruit at a lower margin while keeping their vineyards productive. Today, that safety net is full of holes — the bulk market is oversaturated, prices are at historic lows, and demand isn’t keeping up with supply.

Since 2012, the global wine industry has been overproducing by nearly 3 billion liters annually, creating a long-standing surplus problem. This has led to a backlog of bulk wine sitting in tanks in California as wineries struggle to move inventory before committing to new contracts.

The numbers tell the tale: bulk wine prices have plummeted. What once fetched $30–$40 per gallon now sells for just $10–$15 or even less, if it sells at all. Some growers who depended on bulk sales to cover production costs now face losses or are stuck with unsold fruit.

One factor that few in the industry discuss is the impact of foreign bulk wine imports on the already saturated market. In 2024 alone, California wineries imported nearly 30 million gallons of foreign bulk wine, a decrease from over 65 million in 2022. This suggests that while California growers were advised to leave grapes on the vine and remove thousands of acres to balance supply, the state’s largest grape buyers were actively sourcing bulk wine from abroad. It’s a stark contrast that raises questions about why the local surplus isn’t being absorbed before resorting to imports and whether California growers are being pushed out of their own market.

With bulk wine prices bottoming out and foreign imports increasing competition, the traditional safety nets for surplus grapes and wine look weaker than ever. Selling at a loss is becoming the only option for many growers, and others face difficult decisions about scaling back production, uprooting vines, or hoping for a market correction.

Brandy & Distillation: A Limited Lifeline

Turning surplus grapes into brandy or other spirits sounds like a solid backup plan, but in reality, it’s not a common solution. Sure, some distilleries can take on extra fruit, but not all grape varieties are suitable for distillation.

Setting up or expanding a distillation operation requires specialized equipment, permits and long-term investment. Most wineries aren’t eager to take this on, especially in a market already full of uncertainty.

Then there’s the demand issue. Brandy and fortified wines don’t have the same pull as they once did. Some regions in Europe have turned to government-funded distillation programs to deal with excess wine, but California doesn’t have that kind of safety net.

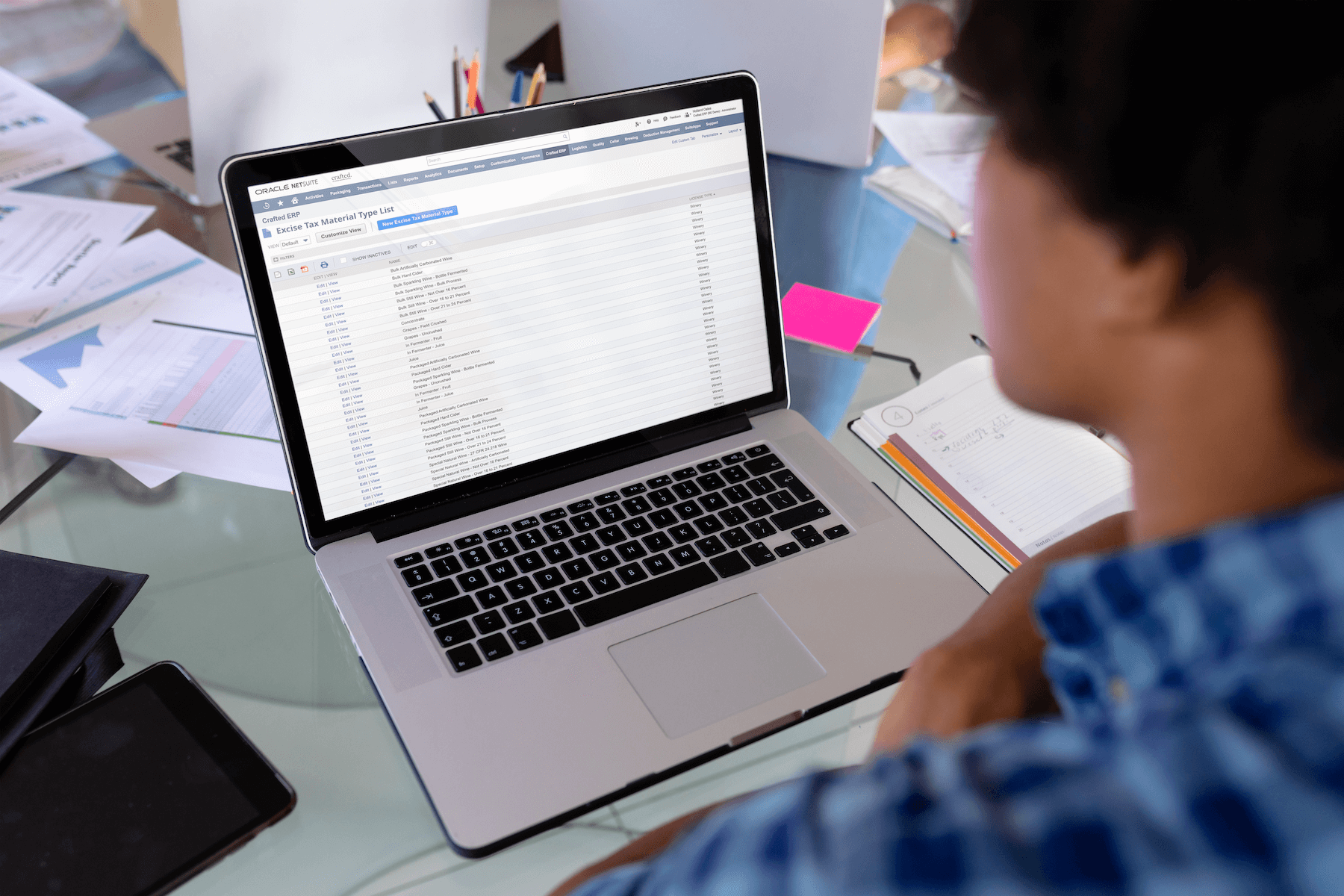

Winemakers are getting creative by expanding beyond traditional wine production. From distilling spirits to experimenting with beer-wine hybrids, RTDs and NA varieties, diversification is one way to weather market shifts. However, it also comes with added complexity. Different beverage types mean different production workflows, compliance requirements and tax structures, all of which must be accurately tracked.

This is precisely where Crafted ERP BevX comes in. Designed for multi-beverage operations, BevX allows producers to manage multiple production types within one system, from batch tracking to regulatory reporting across wine, beer, spirits and alternative beverages. Instead of struggling with disconnected tools or trying to retrofit winery software for distillation or brewing, producers can seamlessly integrate new product lines without losing control over inventory, compliance or profitability.

The right technology can mean the difference between a smart pivot and an operational nightmare for wineries looking to expand into spirits, NA wine or hybrid beverages. As the industry looks for new ways to manage surplus grapes, the ability to adapt quickly and efficiently is more important than ever.

Composting & Agricultural Repurposing: The Last Resort

When all else fails, growers have one final option: let the fruit rot or repurpose it as compost or animal feed. While this approach is at least environmentally friendly, it’s also a (mostly) zero-revenue solution.

Many winemakers and growers are looking for better ways to use surplus fruit before it reaches this stage, whether through sustainability-focused products, new fermentation techniques or even collaborations outside the wine world. That’s where novel solutions offer new ways to turn excess grapes into valuable assets instead of wasted inventory.

Novel Approaches: Creative Ways to Use Grape Surplus

Grape-Based Skincare Products

Winemakers aren’t the only ones interested in what’s inside a grape — the beauty industry has taken notice too. Grape skins and seeds are packed with antioxidants and polyphenols, making them a natural fit for skincare.

Beauty brands have started using grape extracts in moisturizers, serums and exfoliants, tapping into the growing demand for natural, upcycled ingredients. Instead of leftover grape material going to waste, it’s being turned into luxury skincare products with a sustainability angle.

Taking It One Step Further: Spa Treatments

If grapes are good for your skin, why not soak in them? Many high-end spas offer wine-inspired treatments, like The Wine Spa in Portland, Oregon, which uses Willamette Valley grapes in its wine baths.

This kind of vinotherapy — where grape-based compounds are used in facials, scrubs and soaks — has been popular in Europe for years and could easily expand as a unique experience for wine country visitors.

Partnerships with local spas or on-site vineyard wellness experiences could provide an alternative way for wineries to diversify and monetize surplus fruit. Imagine a wine country getaway where visitors sip wine and soak in it — an experience that blends luxury, sustainability and the unique terroir of each region. As wellness tourism continues to grow, there’s real potential for this trend to expand beyond a novelty into a sought-after part of the wine experience.

Turning Grapes into Leather

It turns out grapes aren’t just good for drinking — they can be worn too. A few companies, like VEGEA, have figured out how to turn grape skins, seeds and stems into a sustainable leather alternative.

With growing demand for eco-friendly, animal-free materials, surplus grapes could find their way into everything from handbags to car interiors.

Upcycled Culinary Ingredients

There’s also plenty of potential in the kitchen for repurposing grape byproducts. Grape pomace — the skins, seeds and stems left after pressing — has long been considered winemaking waste, but it’s now finding a second life as a high-fiber, nutrient-rich ingredient. When dried and milled into flour, it can be used in baked goods, pasta and snack foods, adding depth of flavor, texture and natural color while reducing food waste. Producers have even experimented with grape-based protein powders, capitalizing on the growing interest in plant-based nutrition.

Grape seed oil is another byproduct of winemaking that has found a place in the culinary and cosmetic industries. Cold-pressed from discarded seeds, it’s used in salad dressings, sautéing and gourmet infusions, and offers a mild flavor and high smoke point.

Beyond flour and oil, companies are exploring ways to integrate grape derivatives into everyday foods. Brands are incorporating grape pomace into chocolate, granola and energy bars, touting its potential benefits as a source of natural polyphenols and dietary fiber. Even grape-infused vinegars and sauces are making their way onto specialty food shelves, offering a zero-waste approach to flavor innovation.

Instead of viewing pomace and seeds as waste, winemakers and food producers are beginning to see them as premium, sustainable ingredients. Grape byproducts could play a crucial role in the movement to reduce food waste while generating high-value, innovative products.

Natural Food Additives

The wine industry is also looking at food preservation and enhancement. Grape skins and seeds contain natural antioxidants, which can help extend shelf life and boost flavor without relying on artificial preservatives. This fits right into the clean label movement, where consumers want fewer synthetic additives in their food.

What’s Next: The Future of Surplus Management

California’s grape surplus is part of a larger market correction that will likely take years to stabilize. With declining wine consumption, shifting consumer preferences, and economic pressures forcing wineries to rethink their production models, growers and producers must adapt. But what will that look like?

For some, the solution will be scaling back by removing underperforming vines, cutting contracts and focusing on what they can sell. For others, it means exploring new revenue streams, whether through bulk sales, alternative product lines or partnerships outside traditional wine markets. Technology will also play a significant role, helping producers gain better insights into forecasting, inventory management and demand planning.

One thing is certain: the industry is in transition. Those who adapt quickly, embrace new opportunities and leverage data-driven decision-making will be best positioned to weather the shift. The wineries and growers who take a proactive approach will thrive in the next chapter of the California wine industry.

Are you ready to join forward-thinking winemakers? Contact us to learn about our winery-focused ERP solution or software to manage multiple beverage categories and product lines.