Running a brewery is a complex balancing act. Between sourcing raw ingredients, managing production schedules and making sure you correctly balance supply vs. demand, it can seem nearly impossible to keep track of it all.

Enter brewery supply chain software: your super-smart assistant to help manage every aspect of production and operations. These systems will enhance efficiency, optimize workflows and simplify repetitive processes to create a more profitable and sustainable business model. Let’s dive into ways supply chain software can benefit your brewery.

Why Should You Care About Supply Chain Software?

With the changing landscape of brewing, there’s a need for technology solutions that streamline operations and produce tangible, measurable benefits. Supply chain software offers just that — delivering the ingredients you need for enhanced productivity and cost savings.

Automation Helps Teams Work Faster & Smarter

Let’s face it: teams that can accomplish more in less time are happier and more engaged. Supply chain software helps speed up production processes, creating a culture that values efficiency without sacrificing quality.

Instead of relying on rough estimates or labor- and time-intensive inventory counts, manage your stock digitally with brewery supply chain software. You can track inventory in real time and across multiple warehouses or locations.

Supply chain software also helps you seamlessly merge production planning and distribution. You can oversee everything from raw materials stored in the warehouse to the distribution of your finished products. By automating production scheduling, you can maintain the perfect balance between capability and demand.

Efficiency Leads to Reduced Waste & Costs

Profit margins matter. Any waste or inefficiency can be a serious drain on your resources – and the resources around you.

Brewery software can actively monitor your production cycles and inventory to help identify areas of excess waste. It can suggest targeted solutions that will improve your bottom line and help you be more environmentally responsible.

For example, supply chain software can alert you to a surplus of raw materials that are at risk of spoilage. This prompts you to adjust production schedules or manage storage conditions. It also helps you recognize patterns of slow-moving products to reduce overproduction and any associated storage costs.

By automating these processes, breweries can focus more on crafting excellent beers and spend less time fretting about cost inefficiencies. Your brewery will become leaner, greener and more competitive, a toast-worthy achievement indeed.

How Does Supply Chain Software Improve the Quality of Beer?

The backbone of any good beer is a high-quality hop, making ingredient management a top priority for breweries. Supply chain software allows you to address two critical elements of raw ingredient management: maintaining quality and consistency and efficient forecasting and demand planning.

Ensure Product Quality & Consistency

Once you’ve created a distinct, signature recipe of a specific beer, you must ensure that the quality and flavor remain uniform in every batch. This can often be challenging because of seasonal variations in crops and fluctuations in market availability. Here’s where supply chain software steps in:

- It aids in real-time monitoring of quality – Brewing software can trace the source of your hops, grains and other ingredients back to individual farming lots. This data provides insights into the environmental conditions and farming practices that influence the quality of your ingredients.

- It manages hop varieties and other raw ingredients – Different beers styles are made of various hops and other ingredients. Supply chain software keeps track of the different components you need for each of your brews, so you never lose that distinct flavor profile.

Predict & Plan for Consumer or Seasonal Demand

Once you start growing and producing a wider variety of beer, it will be critical to predict how much you’ll need of each product and the ingredients it will require to produce them. This can be a complex and time-consuming process for breweries, but supply and demand planning software can help.

- Anticipate your supply needs – Based on historical brewing data and upcoming production plans, supply and demand planning software can help you forecast your hop requirements. This ensures you have all ingredients available when you need them, and helps prevent overstocking or shortages.

- Switfly respond to changing consumer tastes – With real-time data and ingredient tracking, you can quickly respond to shifts in market trends. If a particular beer style gains popularity, you can ramp up production, and just as swiftly, reduce production for less-favored styles.

- Streamline your order management – Manage orders more effectively with accurate forcasting tools. Supply chain software simplifies order tracking, the receipt of goods and order payments. This frees up valuable time and resources for your team.

By enhancing the efficiency of these two key areas, breweries can improve beer quality and ensure consistency batch after batch. That’s a win-win for you and your customers.

Can Brewery Software Help You Be More Resilliant to Supply Chain Disruptions?

The craft beer industry faces many uncertainties that require careful planning and proactive risk management. A resilient supply chain can help you navigate these challenges and maintain smooth operations.

Mitigate Risks & Manage the Unknown

Brewers know a thing or two about dealing with uncertainty. Confronting risks requires meticulous planning and adaptability, both of which are achievable with supply chain software.

- Identify potential supply chain disruptions – Advanced algorithms can analyze past data to spot trends and potential pitfalls in your supply chain. This includes changes in hops quality, ingredient availability and delivery delays.

- Create a plan A, plan B, plan C…and beyond – Use insights from your supply chain software to strategize possible responses for identified risks. Planning for multiple contengencies keeps you a step ahead and primed to act swiftly when faced with any disruption.

Build Stronger, Long-term Supplier Relationships

How does that old adage go? Keep your friends close and your suppliers closer? Something along those lines. Supply chain software helps maintain these crucial supplier relationships and prevent possible production interruptions.

- Maintain better communication across channels – Good relationships rest on clear, consistent communication. Supply chain software systems provide streamlined communication channels with suppliers, aiding in transparency and collaboration.

- Foster trust with your partners – On-time payments and honoring contract commitments build trust. Easily managing these aspects with the use of brewery software nurtures long-term supplier partnerships that are crucial for business growth.

You can create a resilient, future-proof supply chain ready to endure whatever may happen by reinforcing these two important areas of operations. Keep your focus on crafting great beer, while your supply chain software keeps operations running smoothly.

The Bottom Line About Supply Chain Software

By investing in brewery supply chain software, you’re investing in the future of your business. It’s a tool that can help you stay ahead of the competition, deliver high-quality beer, and achieve your growth plans.

So, if you’re ready to take your brewery to the next level, it’s time to consider supply and demand planning software. Your future self will thank you.

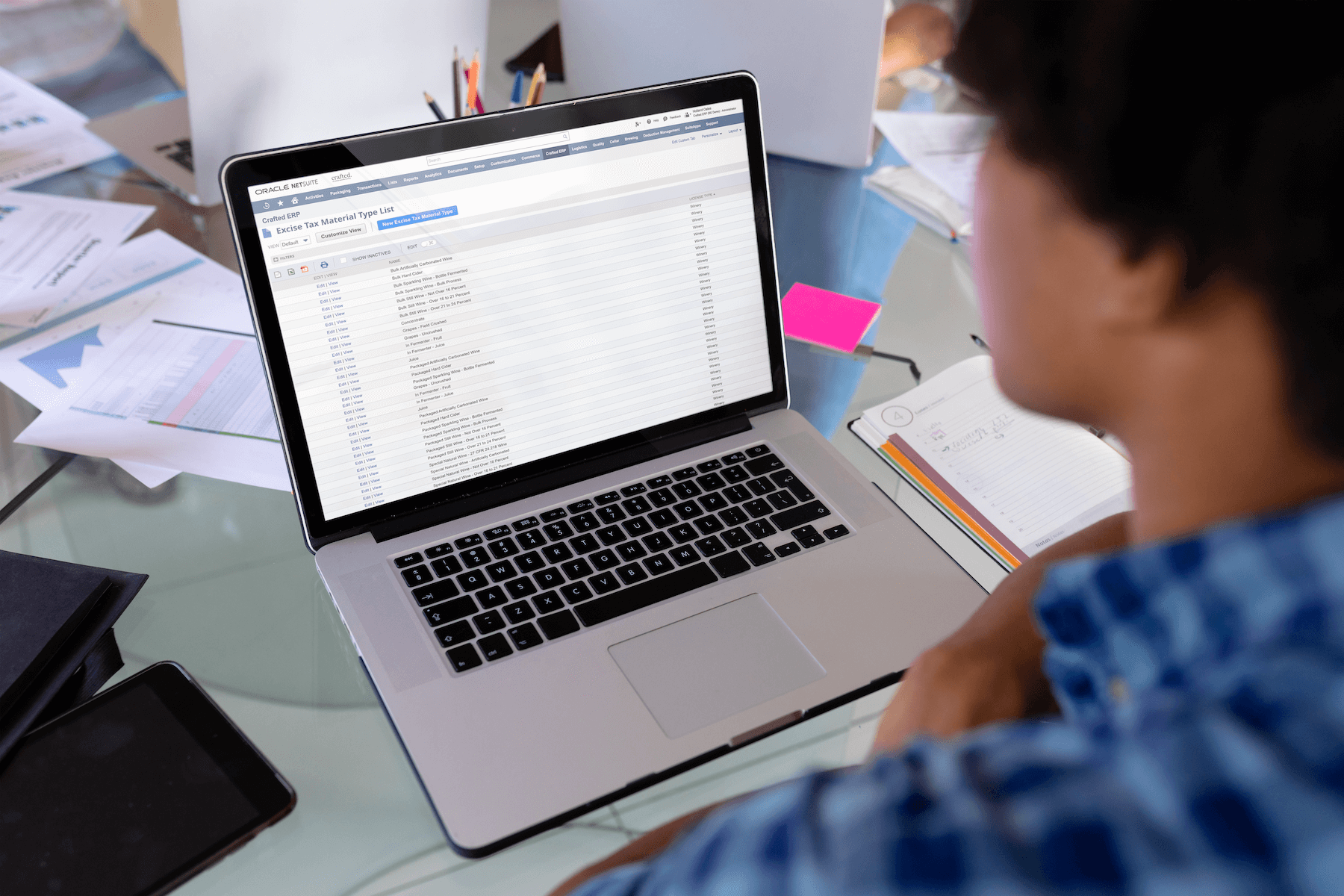

Want to learn more? Let us know if you have any specific questions about supply chain software or the brewing industry. Crafted ERP has tools to manage supply and demand planning, beer production, barrel and keg management, accounting, compliance, sustainability and more.

Frequently Asked Questions

How does brewery supply chain software contribute to cost reduction in brewing operations?

Supply chain software contributes to cost reduction in brewing operations by automating and streamlining critical processes such as inventory management, production scheduling and raw material tracking. It reduces waste by monitoring production cycles and inventory levels closely, and pinpoints areas of excess or inefficiency.

Supply chain software can alert breweries to a surplus of raw materials that might spoil or identify slow-moving products. This helps prevent preventing overproduction and excess storage costs. With these optimizations, breweries can focus on creating quality beers instead of expending resources on unnecessary expenses.

Can brewery supply chain management tools help in predicting and adapting to market demand changes?

Yes, brewery supply chain management tools are specifically designed to help predict and adapt to changes in market demand. This is achieved by analyzing sales data and providing insights into consumer buying behaviors and preferences. The software helps breweries align production with demand fluctuations. It also ensures breweries have the right amount of product available when consumers need it.

Real-time data helps breweries can quickly adjust to trends and maintain balance between supply and market demand. For example, a brewery can know when to increase production for a beer style growing in popularity or decrease it for those less favored, maintaining a balance between supply and market demand.

What are the key features to look for in supply chain software tailored for breweries?

When searching for brewery-specific supply chain software, it’s important to look for key features that address the unique needs of the craft beer industry. This includes real-time inventory management to accurately track raw materials and finished products, production process automation for planning and scheduling, and forecasting tools for hops demand and supply planning. Quality and consistency tracking, particularly for hops, is essential for maintaining the taste profile of beers. Robust data analysis for market trend monitoring and consumer preference insights are critical for responding to changes and informing new beer development.

Additionally, risk management capabilities for planning contingencies and supplier relationship management tools for fostering collaboration and trust are essential to building a resilient supply chain. Together, these features enable breweries to optimize costs, ensure product quality and availability, and maintain competitiveness in a dynamic market.