Sustainability in beverage production. It’s a big ask. Whether you’re making wine, brewing beer, distilling, or crafting cans of zero-proof cocktails, there’s no escaping the growing and necessary demand for greener practices that power sustainability.

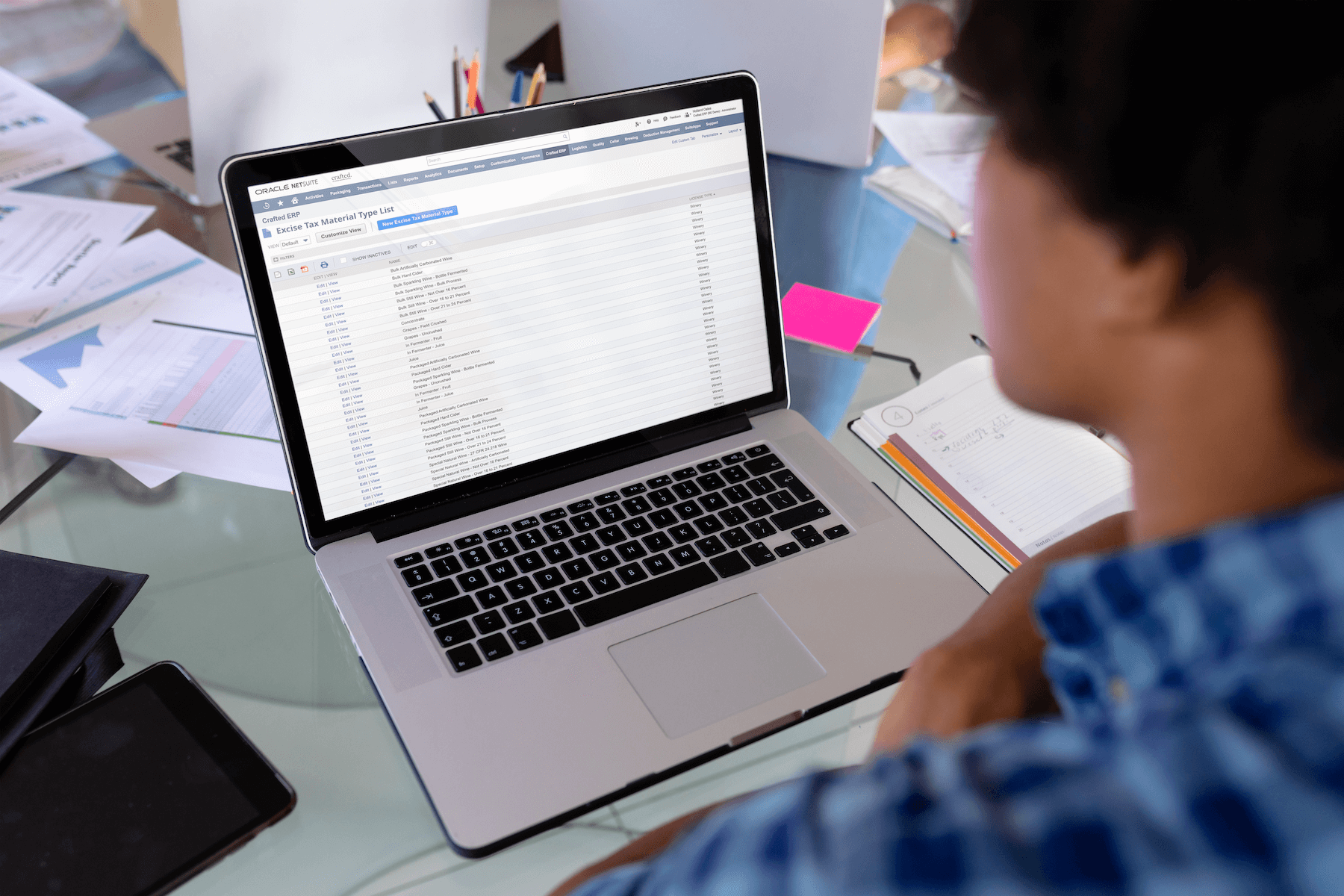

The good news? ERP systems, including Crafted ERP, are uniquely designed to make sustainability both achievable and measurable.

Let’s talk about how.

Tracking What Matters: Sustainability Metrics

Every business wants to do better, but you can’t improve what you can’t measure. That’s where an ERP system with built-in sustainability tracking steps in. By monitoring key metrics like electricity usage, fuel consumption, water use, CO2 emissions and waste across operations, businesses gain a data-driven roadmap for sustainability. No guessing games involved.

An ERP tracks and benchmarks against industry standards, creates audit-ready reports, and identifies areas for improvement. By integrating these into everyday processes, beverage companies can align with the growing focus on sustainability. The result? Better decisions and clearer priorities across the entire operation.

Many ERP solutions come with pre-set sustainability metrics that can be configured to track the specific data a company values, from sustainable packaging efforts to waste reduction initiatives.

Let’s take a look at some key metrics for sustainability and how an ERP system supports them.

Electricity Usage

Energy consumption is a cornerstone of beverage production, from brewing and bottling to refrigeration and lighting. Monitoring electricity usage across facilities reveals areas of inefficiency, such as outdated equipment or unnecessary energy use during off-hours.

By addressing electricity usage, businesses can reduce energy consumption, lower costs and decrease their carbon footprint. Upgrading to energy-efficient machinery, adjusting production schedules, or implementing automated lighting systems are just a few strategies that can make a measurable difference in achieving sustainability.

Fuel Usage

Fuel powers transportation, delivery fleets and certain types of equipment, but it’s also a significant source of emissions. Producers gain insights into where improvements can be made by tracking fuel usage.

Optimizing delivery routes is a particularly practical approach for sustainability in beverage production. Planning efficient paths and consolidating deliveries reduces mileage, fuel consumption and emissions.

CO2 Emissions

Managing carbon emissions is critical to reducing environmental impact and promoting sustainability. By tracking CO2 output, producers can identify high-emission activities and take steps to address them. This might include switching to renewable energy sources for production facilities, improving equipment efficiency, or reducing transportation-related emissions.

Beyond internal benefits, having a clear handle on emissions data makes it easier to communicate progress to customers and stakeholders, showing a genuine commitment to sustainability in beverage production.

Water Usage

Water is an essential resource for beverage production but is also one of the most at-risk resources globally. Tracking usage helps producers identify inefficiencies, like excessive cleaning water or inefficient cooling processes, and make changes to conserve.

Some businesses have implemented water recycling systems or switched to dry cleaning methods for equipment, saving thousands of gallons annually and reducing strain on freshwater supplies.

Wastewater Management

How water is handled after use matters as much as how it’s consumed. Tracking wastewater provides insight into treatment processes, compliance with regulations, and opportunities for reuse.

For example, treated wastewater can often be used for cleaning or irrigation, reducing reliance on fresh water. Proactively managing wastewater also demonstrates a commitment to protecting local ecosystems.

Waste Disposal

Every production process generates waste, but tracking it is the first step toward minimizing it. Identifying the types and volumes of waste produced allows businesses to prioritize reduction efforts, such as rethinking packaging, repurposing byproducts or improving production line efficiency.

Small changes, like using reusable materials or lightweight packaging, can have a significant impact over time.

Recycling Efforts

Recycling programs only succeed with proper tracking and attention. Monitoring recycling data ensures that materials like aluminum, glass and cardboard are properly diverted from landfills.

This data can provide insights to fine-tune processes, such as improving sorting systems or educating staff. Effective recycling benefits the environment, reduces waste disposal costs, and can improve sustainability.

Composting Organic Waste

For producers working with organic ingredients, composting is an ideal way to manage waste sustainably. Ingredients like fruit scraps, coffee grounds and spent grains can be turned into compost instead of ending up in landfills.

Tracking composting efforts helps businesses understand how much waste they’re diverting. It can even open the door to partnerships with local farms or community gardens, creating value beyond their own operations.

Sustainability in Beverage Production: Metrics for Meaningful Change

Tracking these metrics will help guide decisions, set priorities and measure progress. Whether optimizing energy use, conserving water or reducing waste, each step toward sustainability contributes to a better, more sustainable future.

Sustainability is a critical focus area for beverage producers, not just as a response to regulations or consumer demand, but as a way to future-proof operations. By taking a data-driven approach and leveraging ERP solutions with built-in sustainability tracking, beverage companies can align environmental responsibility with long-term success, proving that sustainability and profitability can go hand in hand.

Ready to get started? Drop us a line. We’d love to hear your sustainability goals and how Crafted ERP can help you get there.

Looking for more information on sustainability in beverage production? Check out this Tech & Sustainability webinar, which covers tech investments that support sustainability goals and how you can reduce costs, streamline operations and deliver on the values your customers care about most.